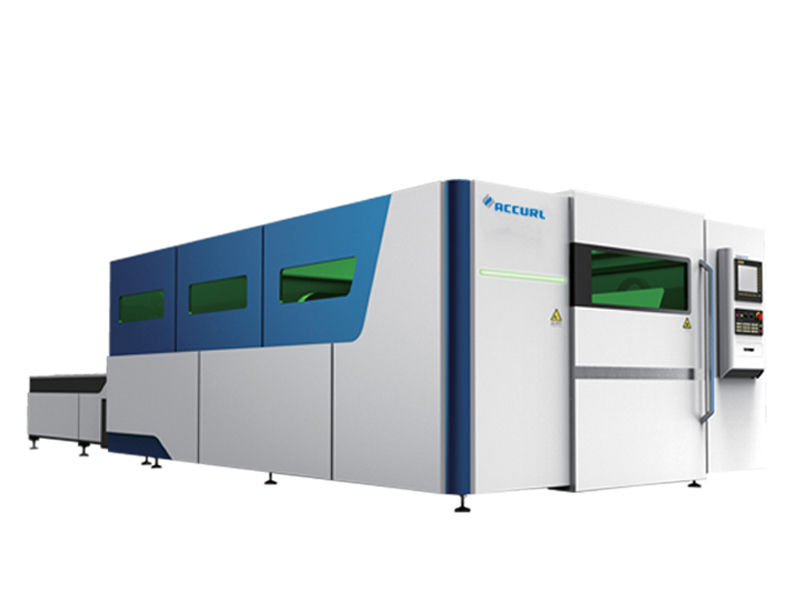

Features

1. Excellent Path Quality: Smaller laser dot and high work efficiency, high quality.

2. High Cutting Speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable Running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High Efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low Maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7 Easy Operations: fiber line transmission, no adjustment of optical path.

Quick Details

Application: Laser Cutting

Condition: New

Laser Type: Fiber Laser

Applicable Material: Metal

Cutting Thickness: 0.2-12mm

Cutting Area: 3000*1500mm or 2400*1500mm

Cutting Speed: 25m/min

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: Cypcut

Graphic Format Supported: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certification: CE, ISO, FDA

After-sales Service Provided: Engineers available to service machinery overseas

Item: cnc laser cutting machine

Machine Size: 2.4*4.7*1.9m

Power Requirements: 380V/50Hz/16A

Continuous Working Time: 24Hours

Max. Cutting Speed: 25m/min

Cutting Depth: 0.2-6mm

Min. Line Width: 0.1mm

Driving and Transmission Way: Imported Servo Motor and Linear Guide Rail

Warranty: 3 years

MOQ: 1 set Small Size Laser Cutting M

Specification

| Model | F3015 | F2015 | Option |

| Max Cutting Range | 3000*1500mm | 2000*1500mm | According to Demands |

| Machine Size(L*W*H) | 2.4*4.7*1.9m | 2.4*5.7*1.9m | |

| Accessory Parts(L*W*H) | Chitler 1*1*1.2m Control Box 1*0.8*1.8m Fiber Module 0.5*0.6*0.14m | ||

| Laser Medium | Single Core Junction Semiconductor Module | ||

| Max Cutting Speed | 25m/min | ||

| Cooling Way | Water Cooling | ||

| Laser Power | 500W(Option 200W/300W/400W/1000W/2000W) | ||

| Min Line Width | 0.1mm | ||

| Cutting Depth | 0.2-6mm | ||

| Driving and Transmission Way | Imported Servo Motor and Linear Guide Rail | ||

| Power Requirements | 380V/50Hz/16A | ||

| Continuous Working Time | 24Hours | ||

| Related Weight | Machine Body 2732kg Trolley 116kg Computer Cabinet 56kg Servo Cabinet 75kg Transformer 77kg Chiller 93kg Fiber Module 50kg | ||

Our Package Advantage:

1. Our Wooden Case is after fumigation treatment.Needn’t timber inspection,saving shipping time.

2. All the spare parts of the machine were bovered by some soft materials,mainly using Pearl Wool. Avoiding all damages that could happen in the delivery process.Then we’ll covered plastic wrap out it tightly,make sure intact of the covered soft materials,also avoiding Waterproof and rust proof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has firm iron jack,convenient to Handling and transport.