Product Description

1.High-quality laser optics system and excellent attachments. Best quality with best price.

2.Efficient and stable programing and control system, easy to learn. Compatible with many kinds of CAD files and formats. Intelligent-layout and cost-saving.

3.Energy-saving and cost-saving. Laser machine is stable and easy to maintain.

4.No need mold and flexible manufacturing, which can meet any requirement of all kinds of special workpieces.

5.Highly-efficient cutting and good cutting effect. No noise and no vibration. Cutting speed can be up to tens of meters per minute when cutting thin metal sheet. Quality for cutting edge is excellent.

6.Imported servo motor, this can make sure to much more improve stability and reliability of laser machines, at the same time can ensure precision of processing.

Fiber Laser Cutting machine Advantages

1) Fiber laser cutting is the fastest process for thin sheet metal.

2) A “clean cut” surface quality is obtained.

3) Reflective materials like aluminium,copper and brass can be cut with ease.

4) Parts process cost is very low.

5 ) Little to no maintenance costs.

6) Consumable part cost is low. The only parts that need to be changed are nozzles, ceramics and protection glasses over long periods. There are no other consumable costs.

7) Resonator life is over 100,000 working hours.

| Model | NC-F1325 | NC-F1530 |

| Type of laser | Fiber Laser | |

| Laser power | 300W,500W, 750W, 1000W, 2000W, 3000W optional | |

| Cutting area | 1300*2500mm | 1500*3000mm |

| Max moving speed | 50m/min | 50m/min |

| Axial positioning accuracy | ±0.04mm/m | ±0.03mm/m |

| Repositioning resolution | ±0.05mm/m | ±0.04mm/m |

| Power requirement | AC380V/50Hz | |

| Max table load | 3000kgs | |

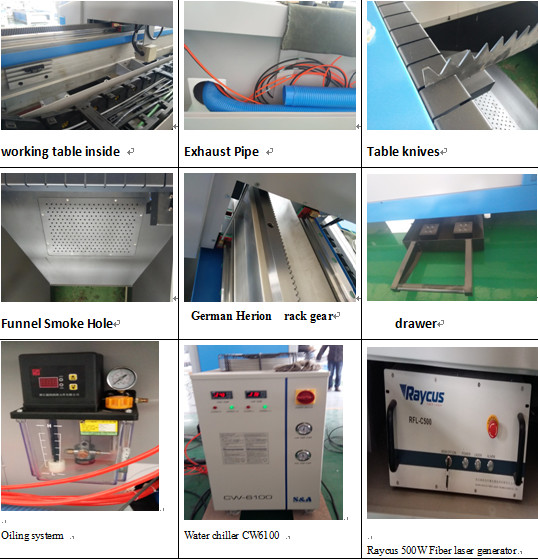

Main parts Show

Quick Details

Application: Laser Cutting

Condition: New

Laser Type: Fiber Laser

Applicable Material: Metal

Cutting Thickness: 10mm

Cutting Area: 1500mm x 3000mm

Cutting Speed: 8M/MIN

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: Cypcut

Graphic Format Supported: AI, BMP, DST, DWG, DXF, DXP, PLT

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Certification: CE, ISO, SGS

After-sales Service Provided: Engineers available to service machinery overseas

Engraving Speed: 25m/MIN

Equipment for electric power:: 87KW

Control System: Cypcut

Max table load: 1600KG

Repositioning resolution: ±0.05mm/m

Axial positioning accuracy: ±0.04mm/m

Power requirement: AC380V/50Hz

Laser power: 500W / 1000W / 2000W

Function: Cutting Metal Materials

Color: Blue