Detailed Product Description

| Model Number: | ECO-FIBER-1530-6000W ACCURL | Working Range: | 1500x3000mm |

|---|---|---|---|

| Laser Type: | USA IPG Fiber YLS-6000w | Transmission: | Taiwan YYC Gear And Rack |

| Laser Head: | Swiss Raytools Auto-following | Table-driven System: | Japanese Yaskawa Servo Motor & Driving System |

| Chiller: | S & A For Laser Source And Cutting Head | Keywords: | Sheet Metal Laser Cutter |

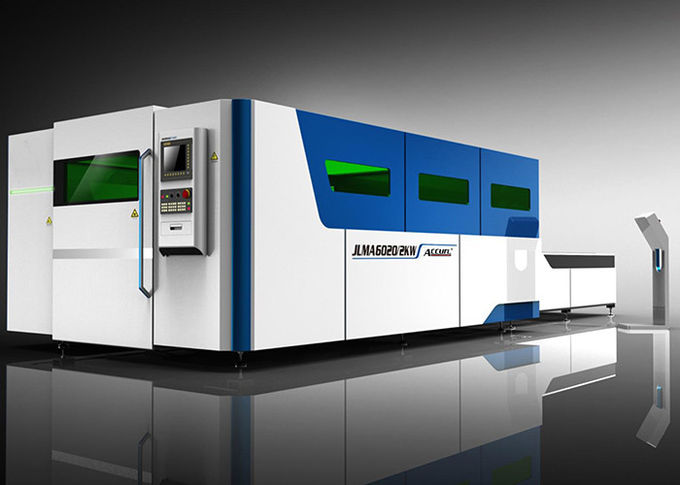

Accurl Band Sheet Metal Laser Cutter 6kw with 3 Axis for 32 mm Mild steel

Product Introduction

The ACCURL Fiber Lasers bring a cost effective, low-maintenance, low operating cost and environmentally friendly solution to your organization. Our fiber laser machines provide quality cutting and tolerances with minimal productivity loss between jobs, equating to a higher return on investment.

• Manufactured by people who use their own machines

• Laser beam transmitted through a fiber optic cable rather than with mirrors and channel tubing resulting in negligible power loss.

• The laser light source has a life expectancy of more than three times that of an equivalent CO2 laser.

• Higher cutting speeds possible

• Dual interchangeable tables allow for faster loading and unloading, reducing downtime

• Laser wavelength is one-tenth of a CO2 laser

• Reduction in cutting variables or tribal knowledge

• Fiber Laser is extremely efficient, equates to very low power consumption

• Low cost of operation, reduced energy cost, no laser gases required to produce beam

• High cutting flexibility (Steel, Stainless Steel, Brass, Copper, Titanium, Aluminum, and more)

• Very few consumables

STANDARD EQUIPMENT

• Stress relieved laser machine frame

• Auto-changing dual pallet system

• Light source

• Chiller

• Radan or Lantek CAD/CAM system

• Precision Rack & Pinion Drive System (Made in Germany)

• 3 lower protective lenses

• 5 Nozzles each of the Following: (1.0mm, 1.2mm,1.5mm, 2.0mm , 2.5mm , 3.0mm)

• 3 Ceramic Nozzle Adapters

• Auto-calibrated nozzle system

• Lens with 5.9” Focus Length

• Smart Slag Collection System/ Chip Conveyor

• Fiber Beam Transmission System (Fiber Cable)

• Operates with both N2 and O2 (cutting) gases

• Home Position Alignment System

• Auxiliary Gas Selector

• Auxiliary Gas Pressure NC function

• Auto Reflection Warning

• Working Lights

• Warning Indicator Lamps

• Lens Cleaning Kit

• Removal and Adjustment Tools

• Ground Plates

• User Manuals in English

OPTIONAL EQUIPMENT

• Linear Drive

• Dust Collection Unit

• Additional Operator Glasses

• Lens with 7.874” Focus Length

• Sheet loading & unloading systems

• Automation & Storage systems

• Automatic Nozzle Changer

• Custom table sizes

• Up to 6 kW laser laser light sources

• Light safety barrier

• Air conditioner for electrical panel

• Metalix, Almacam etc. CAD/CAM software

• LCM (laser cut monitor) sensor for pierce detection and cut loss control

Laser Cutting Machine Live-action In The Fire Control Industry

• The ACCURL Fiber Laser brings a cost effective, low-maintenance, low operating cost and environ-mentally friendly solutions to your organization. Our laser machines provide quality cutting and tolerances with minimal productivity loss between jobs, equating to a higher return on investment. Our fiber laser cutting machines are developed and sold based on these criteria below:

• Manufactured by people who use their own machines.

• The resonator comes with a 100,000 hour (more than 5 years) warranty from the manufacturer (N-light),which also supports cutting high reflective metal materials.

• Higher cutting speeds possible,and high effective cutting ability

• Dual interchangeable tables allow for faster loading and unloading,automatic feeding and collecting device reducing production time.

• Reduction in cutting variables or tribal knowledge

• Fiber Laser is extremely efficient, equates to very low power consumption

• Low cost of operation, energy cost reduced, no laser gases requied to produce beam

• High cutting flexibility (Steel, Stainless Steel, Brass, Copper, Titanium, Aluminum,Carbon steel,Galvanized steel,Alloy steel)

• Laser beam transmitted through a fiber optic.cable rather than with mirrors and channel tubing resulting in negligible power loss.

Application Materials

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Machine Application Field

1. Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2. Application Industries: BODOR Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Techincal Parameter

| Model | ECO-FIBER 3015 / 6KW | |

| CNC Control Unit | FAGOR 8060 CNC System | |

| X axis (Rack & Pinion) | 3000 mm | |

| Y axis (Rack & Pinion) | 1500 mm | |

| Z axis (Ball Screw) | 100 mm | |

| Maximum cutting capacity | Mild stee | 32 mm |

| Stainless steel | 16 mm | |

| Aluminyum | 16 mm | |

| Work piece dimensions | 1525 x 3050 mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 2.5G (25m/s2) | |

| Vector speed | 148 m/min | |

| Absolute positioning accuracy | ± 0.08 mm | |

| Repeatability (X and Y axis) | ± 0.03 mm | |

| Max. load capacity | 2450 kg | |

| High Performance CNC System | FAGOR 8060 from Spain Brand | |

| Laser power | IPG YLS-6 kW from Germany | |

| High Performance Servo motor/drive | FAGOR from Spain Brand | |

| Laser Cutting Head | PRECITEC from Germany | |

| Motoreducer | STOBER from Germany | |