Detailed Product Description

| Model Number: | ECO-FIBER 3015 / 4KW ACCURL | X Axis (Rack & Pinion): | 3000 Mm |

|---|---|---|---|

| Y Axis (Rack & Pinion): | 1500 Mm | Z Axis (Ball Screw): | 100 Mm |

| Maximum Cutting Capacity: | 10 Mm Aluminyum | Product Name: | Fiber Laser Cutting Machine |

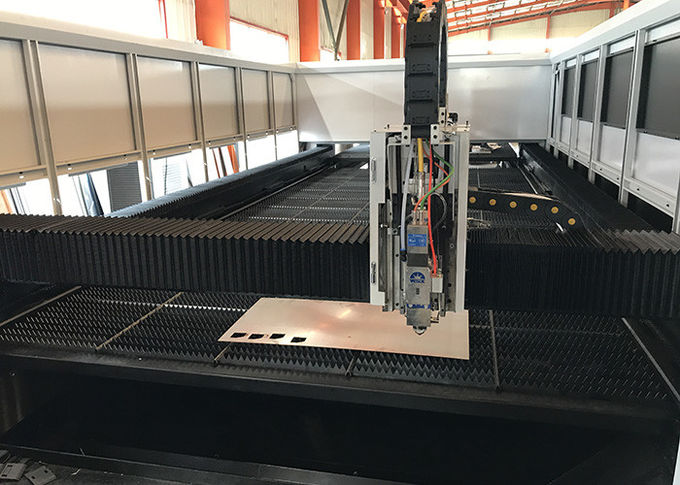

ACCURL IPG 4000W Fiber Laser Cutting Machine with CNC Laser Cutting Machine 4kw Price for Sale

Accurl CNC metal fiber laser cutting equipment main features:

Accurl brand CNC metal fiber laser cutting machine take key components are used abroad leading brand, perfect assembly techniques to create best cutting performance.

Performation in advance mode, the plate quickly punch cutting, cutting time much saved,automatic folloing system, domestic top vibility, can realize a calibrationg, antomatics following, fiber transport, flexible procsssing, suitable for cutting stainless steel, carbon steel and other kinds of high-reflective metal materials.

Product Features

Adopting advanced fiber laser generator and ball screw moving system, it can cut and punch different kind of metal material with high precision and high speed.

Since laser is transmitted by fiber, it is no need to maintenance or adjusts the laser optical path. It greatly reduces the machines fault rate and prolongs the working life.

Large format cutting area meets the demands of various kinds of metal processing.

Applicable Industries for Fiber Laser Cutting Machine

1.Sheet metal fabrication

2. Electrical cabinet

3. Elevator

4. Automotive parts

5. Aviation & aerospace

6. Lighting lamps

7. Metal carfts & decoration

8. Hardware tools

9. Advertising

10. Furnitures

11. Kitchenware equipment

12. Fitness equipment

13. Medical equipment

14. Agricultural and forestry machinery

The advantage of the Suntop CNC fiber laser cutting machines.

Maintenance-free (low maintenance costs):

All-fiber laser optical path entirely composed of fibers and fiber-optic components, welding technology using optical fiber connection between the optical fiber and fiber optic components, the entire optical path is completely enclosed in the optical fiber waveguide. Once this natural all closed optical path is formed, without additional isolation measures can be self-contained, isolated from the external environment to achieve. Resonator fiber grating replaces the lens structure, there is no lens contamination, distortion and so on, so that in case of proper use of fiber lasers, basically no maintenance.

Specification:

| Model | ECO-FIBER 3015 / 4KW | |

| CNC Control Unit | FAGOR 8060 CNC System | |

| X axis (Rack & Pinion) | 3000 mm | |

| Y axis (Rack & Pinion) | 1500 mm | |

| Z axis (Ball Screw) | 100 mm | |

| Maximum cutting capacity | Mild steel | 25 mm |

| Stainless steel | 12 mm | |

| Aluminyum | 10 mm | |

| Work piece dimensions | 1525 x 3050 mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 2.5G (25m/s2) | |

| Vector speed | 148 m/min | |

| Absolute positioning accuracy | ± 0.08 mm | |

| Repeatability (X and Y axis) | ± 0.03 mm | |

| Max. load capacity | 2450 kg | |

| High Performance CNC System | FAGOR 8060 from Spain Brand | |

| Laser power | IPG YLS-4 kW from Germany | |

| High Performance Servo motor/drive | FAGOR from Spain Brand | |

| Laser Cutting Head | PRECITEC from Germany | |

| Motoreducer | STOBER from Germany | |

| Product Name | Fiber Laser Cutting Machine | |