Characteristics of our laser cutting machine

1. Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance.

2. High-performance laser source and stable operating system which make the best cutting effect.

3. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

4. The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

5. The machine is used for cutting a variety of metals with excellent and stable cutting quality.

6. The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

Machine Application Field

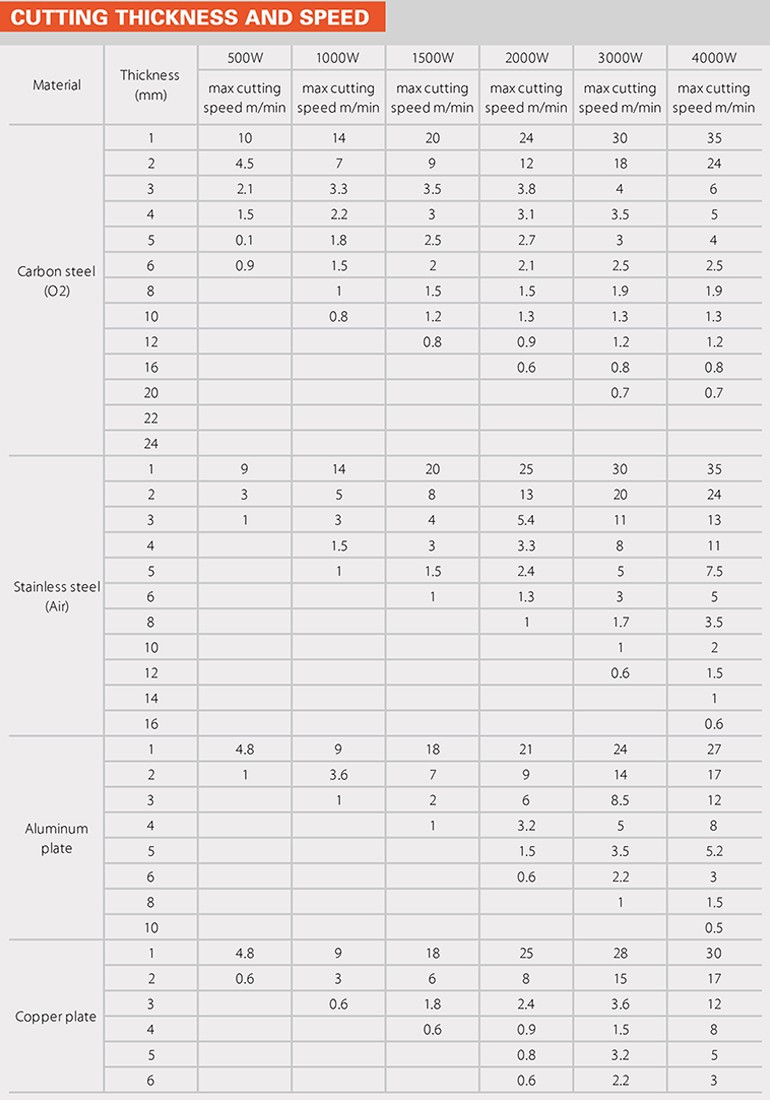

1.Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2.Application Industries: BODOR Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

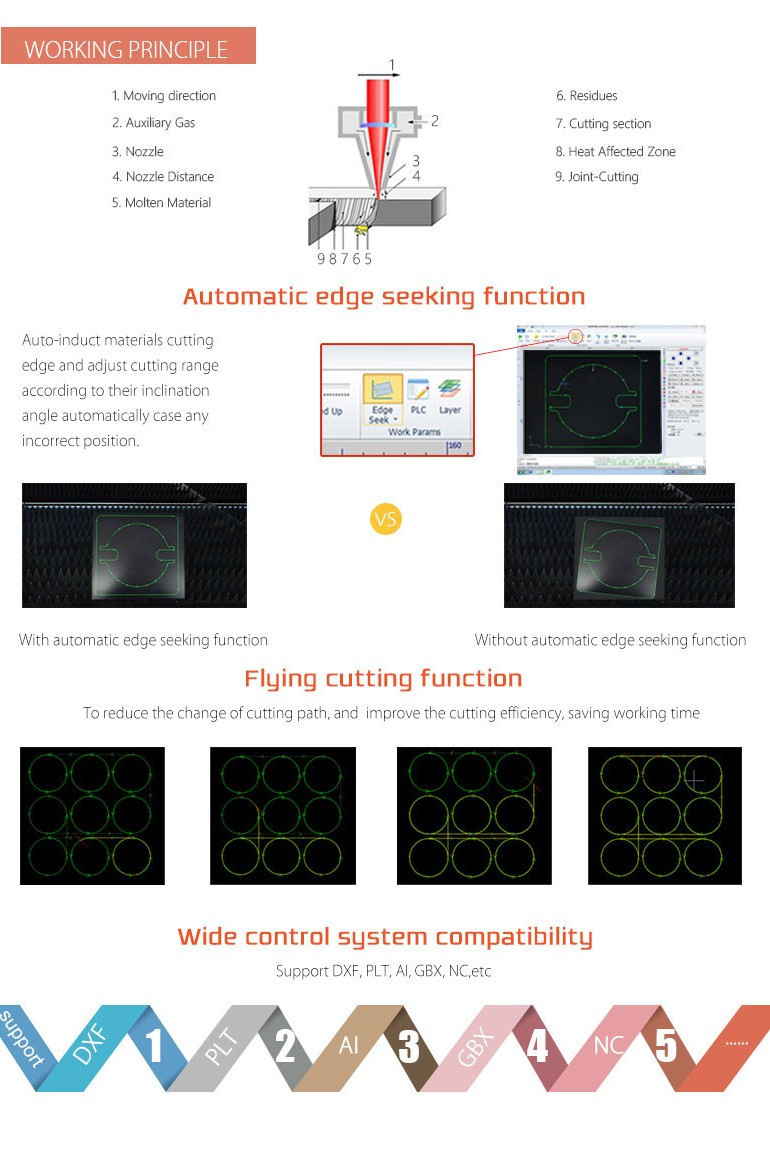

Working Principles

Parameters of laser cutting machine

Quality Control

Quality is our paramount mission that underpinning the lifeline of the company, and it is the most important factor to maintain long-term business relationships with customers. Special attention is paid to the quality of every unit of ACCURL laser cutting machine. Standard quality control system and team are responsible to insure the product quality in every process with different instruments like laser interferometer and laser power meter. The laser interferometer and laser collimator are used through the mechanical assembling process. In the laser assembling process, the laser power meter and optical microscope are adopted.

Warranty and Service

1.Guarantee for 3 years.

2. Maintenance free of charge for 3 years .

3.We will provide the consumable parts at an agency price.

4.24 hours online service, free technical support.

5.Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6.We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance.

Quick Details

Application: Laser Cutting

Condition: New

Laser Type: Fiber Laser

Applicable Material: Metal

Cutting Thickness: According the material

Cutting Area: 1300x2500mm, 1500x3000mm, 1500x4000mm, 1500x6000mm

Cutting Speed: 0.5- 35 m/min

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: Cypcut

Graphic Format Supported: AI, BMP, DST, DWG, DXF, LAS, PLT

Place of Origin:Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: F series

Certification: CE, SGS

After-sales Service Provided: Engineers available to service machinery overseas

Moving speed: 12m/min

Max. cutting speed: 8m/min

application materials: metal plate

Laser power: 500W 800w 1000W 2000W 3000W

Power supply: 380V/50HZ

Driving system: gear and rack transmission

Cutting materials: Stainless Steel Carbon Steel Sheet

tube length: 3meter , 6 meter ...

Name: steel cutting machine price