Detailed Product Description

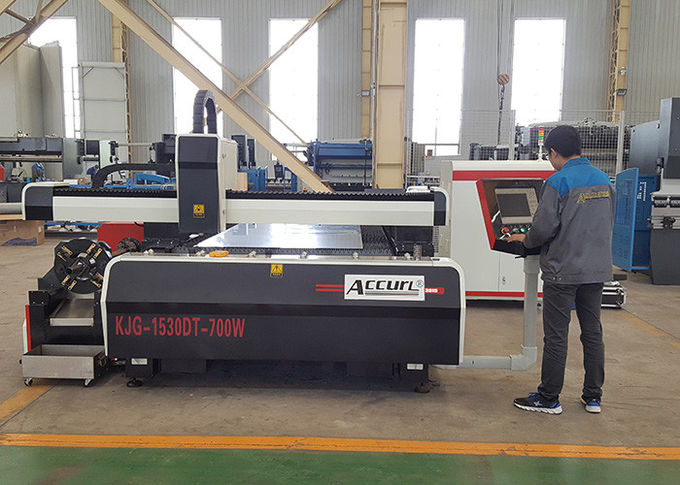

| Model Number: | KJG-1530DT-700W ACCURL | Working Range: | 1500x3000mm |

|---|---|---|---|

| Laser Type: | USA IPG Fiber YLS-700w | Linear Guide: | Taiwan HIWIN |

| Chiller: | S & A For Laser Source And Cutting Head | Keywords: | Laser Cutting Machine Price |

ACCURL 700w Laser Cutting Machine Price for Carbon steel Laser Cutting 8mm

Product Introduction

Our ACCURL team now introduces its newest generation in tube and profile processing technology – the fiber laser tube cutting system. Technological innovation has brought us the Smart KJG Series. With exceptional reliability and high beam quality, our fiber laser cutting machines continue to be leaders amongst the competition.

The Accurl@ Fiber Lasers bring you a cost effective, low-maintenance, low operating cost,environmentally friendly solution to your organization. We deliver a machine that providesquality cutting and tolerances with small productivity loss between jobs, equating to higher returnon investments. Our fiber laser cutting machines are developed and sold based on these criteria.

STANDARD EQUIPMENT

• lUser friendly Cypcut Windows CAD/CAM CNC control unit.

• lUnique features:

• Very easy to operate.

• Quick and easy installation.

• Low investment and operating costs.

• The most cost-efficient solution for every requirement.

• Flexible beam path

• High output power

• High optical quality

• Up to %300 faster cutting

• High wall plug efficiency (>%30)

• Copper, brass cutting ability

• Advanced Raytools cutting head (with air cross blast).

• High performance and high accuracy rack and pinion system.

OPTIONAL EQUIPMENT

• FAGOR 8055 CNC System(Servo motor)

• Shuttle Table and Clean Room

• Table size 1500x4000mm

• Table size 2000x4000mm

• Pipe cutting system(φ220mm / 3000mm)

• Cutting Head from PRECITEC- Manual(500w-1500w)

• USA.IPG / nLIGHT / China.Raycus Fiber Laser Power(500w-2kw)

Configuration of Laser cutting machine

Mechanical platform: the cover, rails, base, composed of reflective frames and other mechanical parts;

Drivetrain: four balanced by the three imported high-precision linear guide, three high-precision ball screw, belt, three stepper motors and several gears;

Auxiliary systems: There are circulating cooling water pump, blowing compressors, smokeexhaust fan;

Optical system: a laser tube, laser power supply, three metal reflection mirrors and a focusing head component.

Advantages of fiber laser metal cutting machine

(1) fiber laser - The high light conversion efficiency, conversion efficiency of over 30%, with little power fiber lasers without chillers, air-cooled, can greatly save power at work, savings in operating costs, the highest productivity;

(2) lasers running power, without generating additional gas laser having the lowest operating and maintenance costs;

(3) Fiber laser using semiconductor modular and redundant design, resonant cavity without optical lenses, no start-up time, with adjustment-free, maintenance-free, high stability advantages, reducing parts cost and maintenance time, which is unmatchd by conventional lasers ;

(4) fiber laser output wavelength of 1.06 microns, is CO2 1/10 wavelength, beam quality output, high power density, is very conducive to the absorption of metallic materials, with excellent cutting and welding capability, so that The minimum cost of processing;

(5) the entire laser cutting machine optical fiber transmission route, and so no complex mirror optical system, the light path is simple, stable structure, external light path maintenance-free;

(6) cutting head contains a protective glass, so valuable and so rarely focusing mirror consumables consumption;

(7) by exporting fiber optic light, so that the design of the mechanical system becomes very simple and very easy to integrate with a robot or a multi-dimensional table;

(8) laser plus shutter You can post a Multi machine, via fiber optic splitter, split into multiple simultaneously multiple, easy to expand functionality, easy to upgrade.

Packing & Delivery

1. Our wooden case is after fumigation treatment.Needn’t timber inspection,saving shipping time.

2. All the spare parts of the machine were covered by some soft materials,mainly using pearl wool.

3. The outmost is wooden case with fixed formwork.

4. The bottom of the wooden case has firm iron jack,convenient to Handling and transport.

Our Service

Pre-Sales Service

• Technical solution.

• Online video authentication machine work.

• Cutting samples provided by DHL.

After-Sales Service

• Training how to instal the machine, training how to use the machine.

• Engineers available to service machinery overseas.

| Model | KJG-1530 / IPG 700w | |

| Maximum cutting capacity | Mild steel | 8mm |

| Stainless steel | 3mm | |

| Aluminyum | 2.5mm | |

| Copper | 1.5mm | |

| Laser Power | YLR-700Watt | |

| Max running speed | 40/min | |

| Work piece dimensions | 1500 x 3000mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 1.2G (12m/s2) | |

| Absolute positioning accuracy | ± 0.03 mm | |

| Max. load capacity | 1550 kg | |

| Fume extractor | 1000 m3/hour | |

| Laser Cutting Head | RayTools BM110 from Switzerland | |

| Feed rate | Programmable up to 30 m/min. | |

| Applied Materials | Thin mild steel, Stainless steel, Aluminum, Copper plate | |