Detailed Product Description

| Model Number: | GSII-PS3516-PMAX-105A | Plasma Power: | Hypertherm Powermax105 USA |

|---|---|---|---|

| Gantry Type: | Table | Effective Cutting Area(Length): | 3700 X 16800mm |

| Flame Cutting Thickness: | 6-350 Mm | Cutting Positioning Accuracy: | ±0.5mm/m |

| Track Span: | Less Than 4000 Using Single Driver | Keywords: | CNC Flame Cutter |

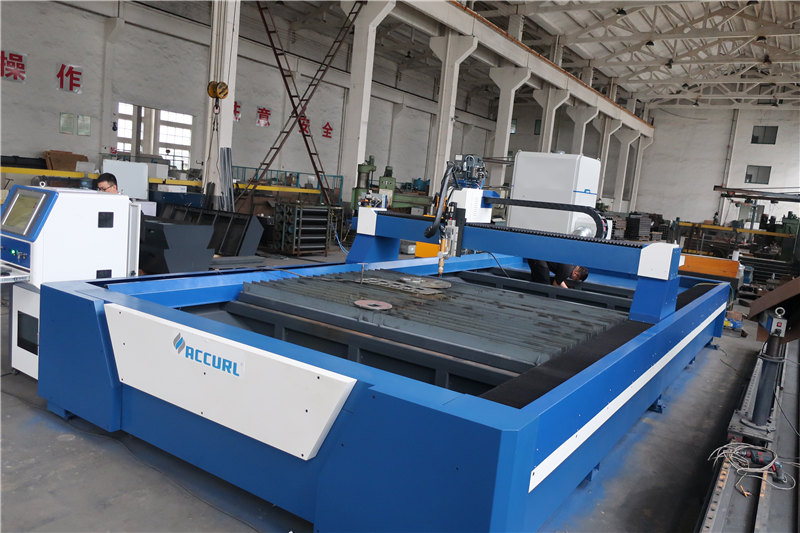

3700 x 16800 Metal CNC Plasma and Flame Cutting Machine , Plasma or Flame Cutter

Brief introduction

The ACCURL CNC flame cutting machine is specially designed for metal plate cutting,it is characterized of high automation and efficiency,easy operation and long service time. This CNC plasma and flame cutting machine is gantry structure with double-driven system, working size can be customized upon requirement.It can be used for cutting carbon steel, stainless steel and non-ferrous metal in any 2d graphics,thus is widely used in metal cutting fields.

Host longitudinal rails imported precision dual axis linear guides, horizontal transmission by a precision aluminum extrusions and components, transmission stability, high accuracy Can cut any complex plane figures for oxyfuel flame cutting and plasma cutting machine, free to move, not accounting for fixed venue. Widely used in automotive, shipbuilding, petrochemical, boiler and pressure vessel, engineering machinery, light machinery and other industries, especially for single-piece contoured surface and mass production.

Fatures

1. Welded lathe bed of thick-wall profiled steel, more solid and stable.

2. Reasonable lathe table design, 10 mm thickness steel plates fixed on lathe table covered by cast sheath with spikes. Steel plates will not be damaged even under raging flame. The level difference of whole double-deck platform remains in 0-1.5mm.

3. Advanced material inclined discharging design. All finished work pieces and fragments slide into both sides of tunnel for safe and convenient collection.

4. Panasonic Servo motor, high accuracy rack transmission. Low noise, stable and accurate coordinate movement.

5. Start control system made in Sino-US joint venture and design Software Type3 and Ucancam with auto material saving function.

6. American Cut-Master power supply (Power: 100A) together with high sensitive arc pressure adjuster. Self-adjusting to choose the best distance between plasma head and work piece automatically in order to ensure cutting accuracy.

7. Best choice for all kinds of different thickness material and heterotypic sheet cutting.

THE STANDARD COMPONENTS

1. The longitudinal, transverse drive are all use high-precision gear and rack.( Class 7 Precision) for transmission. Both longitudinal and transverse have all adopted liner guide rail are imported from Taiwan,China to guarantee the stability in moving, high-precision, durable in usage and good appearance.

2. The reducer is planetary gear reducer for precision in moving and also balance.

3. The drive system is from imported Japan AC servo drive for steady in movement, a wider range of speed transmission, short acceleration time.

The AC servo drive is the UP-TO-DATE JANPAN PANASONIC AC SERIES SERVO MOTOR

THE MAIN CHARACTER

1. High stability and one-time cutting shape process.

2. Adopt new technology for free of maintenance supporting no lubrication, exempt from dust

3. Use South Korea’s Samsung industrial level low power core to control the power consumption below 1500W to be environmental protection and energy saving

4. The machine apply HONGYUDA series arc voltage automatic height adjusting device to ensure the advantage or free of maintenance , high precision in height level control and also the reliability of the product. The machine has equipped with POWERMAX 105 plasma cutting electronic power, good in cutting effect, long life in consumptive components and material to prevent the worry for the exchange for the electrode cutting nozzle.

5. Customer-tailored service for the equipment in demand for example alternative for full step drive type or combination drive machine. And also can choose single fire, single plasma or combination with fire and plasma cutting etc.

6. Optional for wireless remote control function to easily control any emergency when the operator is far away from the machine, can control the start, stop, rise, down, forward or backward within 100M.

Detailed Images

1. Machine Parts

Name: 7-inch color screen CNC cutting system

Brand: JIAODA CNC SYSTEM

Original: China

Display:7 inch high resolution 800*480 16000000 color high brightness LCD screen

Memory:64M SDRAM

User space program:256M

400MHZ system clock frequency

USB:USB 1:1interface front

Keyboard:electronic PCB film keyboard or standard industrial keyboard

Case:whole steel structure completely shielded ,can really achieve anti-electro magnetic radiation,anti-static,anti-interference.

2. Main Features

Name: Plasma torch function interface

Brand: CHD

Original: China

Reserved plasma cutting function interface, support for plasma cutting.

Technical specifications

| Type | ACCURL PS - 3516 |

| Product Name | CNC Flame Cutter |

| Cutting Table | 3700 x 16800 mm |

| Machine Width | 5750 min-1 |

| Machine Lenght | 18200 mm |

| Machine Height | 2200 mm |

| Table Height | 750 mm |

| Table Width | 3700 mm |

| Table Lenght | 14400 mm |

| X Axis Stroke | 4300 mm |

| Y Axis Stroke | 16200 mm |

| Weight | 20000 kg |