Function

(1)Coil material straightening and leveling

(2)Synchronous material loading and cutting

(3)Belt-drive and automatic material loading

Quick Details

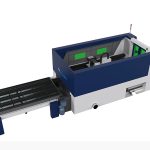

Application: Laser Cutting

Condition: New

Laser Type: Fiber Laser

Applicable Material: Metal

Cutting Thickness: 20mm

Cutting Area: 1500*3000mm

Cutting Speed: 35m/min

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: Cypcut

Graphic Format Supported: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certification: CE, ISO, SGS, FDA,BV

After-sales Service Provided: Engineers available to service machinery overseas

Function: cnc metal laser cutting machine

Working Area: 1300x3000mm

Laser Power: 500W ~4000W

Max. Moving Speed: 100m/min

Max. Cutting Speed: 35m/min

Positioning Accuracy: 0.03mm

Reposition Accuracy: 0.02mm

Min. Line Width: 0.1mm

Cutting Depth: 0.2-6mm

Power Requirements: 380V/50Hz/16A

Features

(1)Integration of fully automated material straightening, leveling, loading and cutting

(2)Automatic assembling line for manpower saving

(3)Guarantee of continuity for production and processing

(4)Net coil material cutting to improve sheet metal utilization rate.

(5)Compact configuration and full-enclosure design for safer and environment-friendly operation.

(6)Rolling cutting platform to avoid material jamming during finished material conveyance

(7)Leveling machine is synchronized with rolling cutting platform for material feeding, to protect underside from scratch during material feeding.

(8)Automatic material loading is facilitated with width limit device to prevent off-track of materials with narrow or wide size and ensure alignment.

Advantage of metal cutting cnc laser machine

1. Excellent path quality: Smaller laser dot and high work efficiency, high quality.

2. High cutting speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7 Easy operations: fiber line transmission, no adjustment of optical path.