A fiber laser is a laser in which the active gain medium is an optical fiber doped with rare-earth elements such as erbium.

The way it generates its beam is distinctly different from that of a Co2 laser which uses resonators.

Fiber lasers are much more ecofriendly than Co2 lasers using typically less than 50% power consumption compared to a Co2 Laser.

They are also more reliable and cut parts up to 6mm thick 30-40% quicker than a Co2 Laser.

Features of fiber laser cutting machine

1.Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2.High cutting speed: cutting speed is more than 20m/min.

3.Stable running: adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours

4.High efficiency for photoelectric conversion : Compare with CO2 laser cutting machine ,fiber laser cutting machine

have three times photoelectric conversion efficiency

5.Low cost: Save energy and protect enviroment.Low electric power consumption.

6.Low maintenance: fiber line transmission, no need reflect lens,save maintenance cost;

7.Easy operations: fiber line transmission, no adjustment of optical path;

Technical Date of fiber laser cutting machine

| Model | fiber laser cutting machine | ||

| Laser type | Raycus fiber laser | ||

| Laser working medium | Fiber | ||

| Laser wavelength | 1064 nm | ||

| Laser power | 300w, 500w, 750w, 1000w etc | ||

| Beam quality | <0.373mrad | ||

| Controlling system 4 axis | Bochu (Made in Shanghai) | ||

| System language | Multi languages | ||

| Cutting head | U.S.26 | ||

| Motor | 750W YASKAWA servo (Made in Japan) | ||

| Speed reducer | Delta | ||

| Transmission and guide rails | Transmission way for X Y axis | Rack gear (Made in Germany) | |

| Guide rails for XY axis | Imported HIWIN Square guide rail | ||

| Ball screw for Z axis | THK ball screw (from Japan) | ||

| Table | Sawtooth | ||

| Water chiller | 1P | ||

| Rotary system | Diameter of rotor | 100mm (can actually up to 150mm) | |

| Length of rotor | according to u request | ||

| Industrial computer | Yan hua | ||

| Effective cutting range | 3000* 1500mm | ||

| Graphic format supported | Auto cad, Corel draw, PLT, DXF, BMP, AI, DST, DWG, etc | ||

| Table axial positioning accuracy | ≤±0.03mm/m | ||

| Repeat positioning accuracy table | ≤±0.02mm/m | ||

| Cutting speed | ≤30m/min | ||

| Max cutting thickness | 10 mm (according to laser power ) | ||

| Maximum table load | 1600KG | ||

| Power Ratings | Three-phase 380V 60Hz | ||

| Power | 6-20KW | ||

| Total power protection class | IP54 | ||

1 Raycus fiber laser generotor

2 US 26 cutting head

3 Bochu controlling system

4 Japan Omron limit switch

5 Water chiller 1p

5 Germany speed reducer

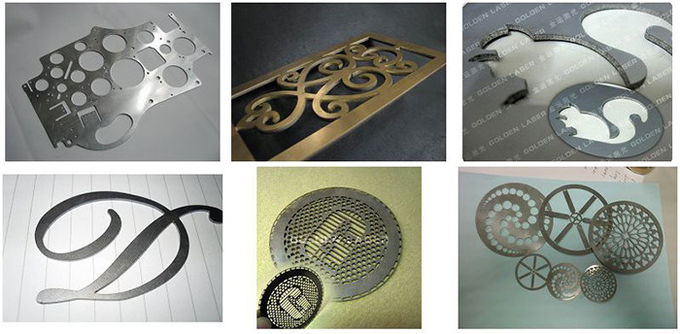

Applications materials of fiber laser cutting machine

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Is suitable for stainless steel, mild steel, carbon steel, alloy steel, spring steel, iron, galvanized iron, galvanized sheet, aluminum,

copper, brass, bronze, gold, silver, titanium plates, metal sheets, metal plates, metal tubes and pipes, etc.

Application Industry:

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs,

Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal ProcessingMetals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing,

Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Cheap 500W CNC Metal Fiber Laser Cutting Machine for Sale

Cutting ability & Consume

| Material | Thickness(mm) | Speed(mm/s) | Gas Pressure(MPa) | Gas | Cutting Height |

| Stainless Steel | 0.5 | >200 | 1 | N2 | 0.6 |

| 1 | 90~120 | >1.1 | N2 | 0.6 | |

| 2 | 16~20 | >1.5 | N2 | 0.6 | |

| Carbon Steel | 1 | 120~150 | 1 | O2 | 1 |

| 2 | 35~45 | 0.6~0.8 | O2 | 1 | |

| 3 | 15~18 | 0.3~0.5 | O2 | 1 |

Our Services

1)24 Months for for the whole machine.

2)All the machines will be full tested before shipment.

3)Laser tube 100000 hours' working time.

4)24 hours technical support-- email, telephone or video online.

5)User-friendly English manual for machine using and maintaining.