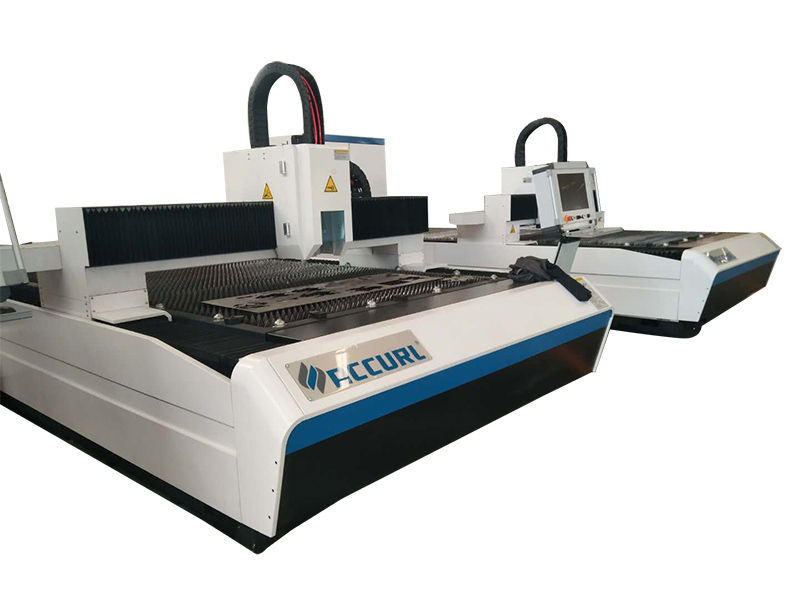

Product Description

LOW EXPENSES

Low input and running cost.

OR-F is the ideal entry-level machine for plate laser cutting, and the working program can be achieved with lower purchase and training cost.

· Inon Cast Bed

The combination of steel and soft.

The exquisite welding process, which guarantees the stability of the bed, has the advantages of rigid, high precision and non-deformation for 20 years.

· CAST ALUMINUM BEAM

High strength, light weight, high speed.

The cast aluminum beam has the characteristics of high strength, light weight and high speed, which improved the performance of laser cutting machine.

· HIGH SPEED

The overall improvement of speed and acceleration.

Maximum operating speed is 45m/min; 1.5G acceleration.

Main Features of laser cutting machine

1. Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance.

2. High-performance laser source and stable operating system which make the best cutting effect.

3. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

4. The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

5. The machine is used for cutting a variety of metals with excellent and stable cutting quality.

6. The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

Model | ACCURL 1530 | ACCURL 1540 |

Working Area | 1500*3000mm | 1500*4000mm |

Dimensions(L*W*H) | 4550*2300*2000mm | 5580*2300*2000mm |

Laser Power | 1000w/2000w/3000w/4000w | |

Weight | 5200KG | |

Repeat Positioning Accuracy | ±0.02mm | |

Accuracy of Positioning | ±0.03mm | |

Max. Movement Speed | 170m/min | |

Max. Cutting Speed | 80m/min | |

Max Acceleration | 1.5G | |

Power Consumption | <10KW | |

Specified voltage and frequency | 380V/50Hz/60Hz/60A(Customizable) | |

Sample

Our Service

Pre-sales Service

1. 12 hours quick pre-sales response and free consulting.

2. Any kind of technical support are available for users.

3. Free Sample Making is available.

4. Free Sample Testing is available.

5. Progressing solution design will be offered to all the distributor and users.

After-sales Service

1. 12 hours Quick Feedback.

· "Training Video", "Instruction Book", and "Operation .Manual" will be offered.

2. Brochures for simple trouble-shootings of the machine is available.

3. Plenty of technical support online is available.

4. Quick Back-up Parts Available & Technical Assistance.

5. Free training service is available.

Warranty

1. Machine machinery parts is 2 years under normally operating machine according to user manual.

2. Laser lens and mirrors warranty is 3 months.

3. Electronic spare parts (motors and motherboard and laser power suply) warranty is 12 months.

4. Damagable spare parts for laser engraving machines

(water pumps, water protective, red dot system, lens limit....)will be sent to u free charge with machine.

QC System

1. Skilled and strict Quality Inspection Team is available during the material purchasing and production procedure.

2. Random sample testing by Quality Control.

3. Traceability for OREELASER machines.

4. Certified according to ISO 9001 and ISO 14001.

5. Certified according to CE and FDA standards.