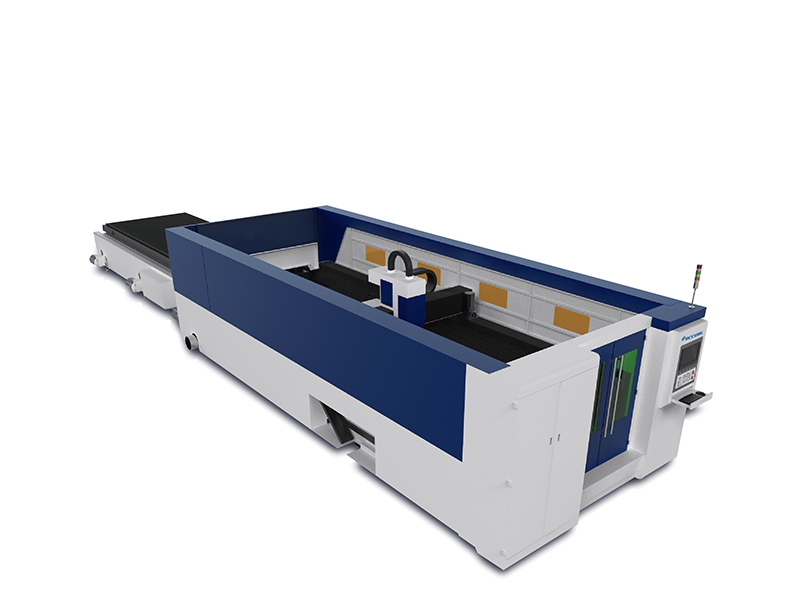

Characteristics of our laser cutting machine

1. Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance.

2. High-performance laser source and stable operating systemwhich make the best cutting effect.

3. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

4. The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

5. The machine is used for cutting a variety of metalswith excellent and stable cutting quality.

6. The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

Quick Details

Condition: New

Laser Type: Fiber Laser

Applicable Material: Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, plastic, Plexiglax, Plywood, Rubber, Wood, Other

Cutting Thickness: 0-20mm

Cutting Area: 3000*1500mm

Cutting Speed: 0-60m/min

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: Cypcut

Graphic Format Supported: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT, metal laser cutting machine

Certification: CE, SGS, FDA

After-sales Service Provided: Engineers available to service machinery overseas

Model: laser cutting machine

Laser Output Power: 1000W/2000W/2500W/3000W/4000W

Moving Speed: 40m/min

Max Cutting Speed: 25mm/min

Cooling Way: Water Cooling

Driving way: imported Servo Motor

Keyword: laser cutting machine

Min line width: 0.1nm

Driving and transmission Way: Imported Servo Motor and Linear Guide Rail

Continuous Working Time: 24Hours