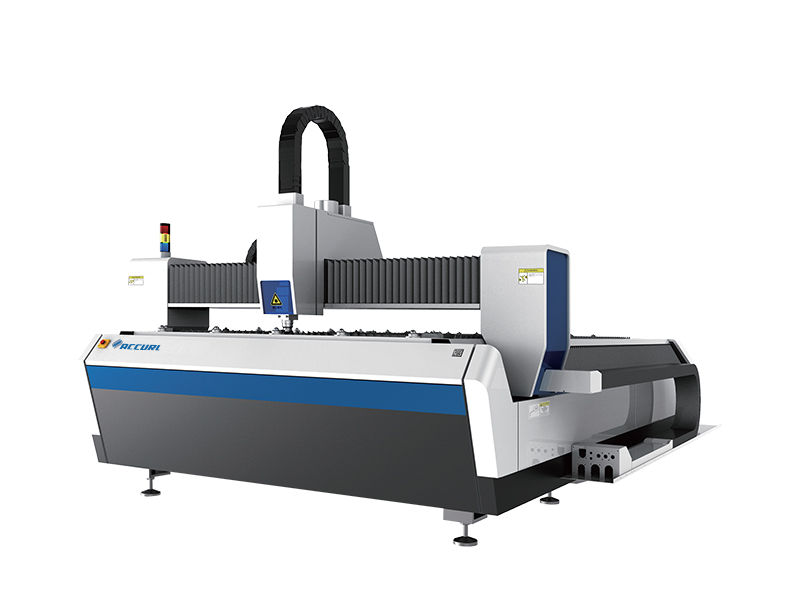

Fiber laser cutting machine Feature

Adopting World Famous Germany Dlaser Fiber laser source and USA Laser Mech cutting head & Dynamic Focus System , it can cut and punch different kind of metal material with high precision and high speed.

Since laser is transmitted by fiber, it is no need to maintenance or adjusts the laser optical path. It greatly reduces the machines fault rate and prolongs the working life.

Large format cutting area meets the demands of various kinds of metal processing.

Fiber laser cutting machine Advantages

1) Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2) High cutting speed: Cutting speed is more than 20m/min

3) Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4) High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine has three times photoelectric conversion efficiency

5) Low cost & Low maintenance: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine. Fiber line transmission no need reflect lens, save maintenance cost;

6) Easy operations: fiber line transmission, no adjustment of optical path;

7) Super flexible optical effects: Compact design, easy to flexible manufacturing requirements.

8). Adopted Original Raycus or German IPG fiber laser source: with long using life up to 150000 hours and high cutting speed up to 15m/min;

9). Japan YASKAWA Servo motor with double ball screw driving system: can make sure the cutting high precision especially comparing with the single driver system.

10). Imported World Famous "LaserMech" laser head with auto focusing height follower: which can ensure the constant same distance between the head and cutting material.

11). The cutting slot is very slim, can reach up to 0.05mm: The machine is very suitable for processing precision parts with high efficiency.

12). Automatic Lubrication System for Mechanic: which can lubricate the linear guiderail nearly 500 times per minute to make sure the high precision.

13). Convenient Collecting System: which has the special funnel design to make collecting more easy.

Applied materials

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Applied Industries

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Technical Data of Fiber Laser Cutting Machine:

| Model | accurl-2513 | accurl-3015 |

| Laser Power | 500W | |

| Laser Source | Raycus or IPG Laser Fiber Laser Source | |

| Laser Type | Imported Fiber Laser or Top Brand China Fiber Laser | |

| Laser Technology | Germany Technology | |

| XYZ Working Area | 2500*1300*150mm | 3000*1500*150mm |

Max. Cutting Thickness (CS) | 1mm - 5mm | |

| Max. Cutting Speed | 5-15 Meters / Min (up to Materials) | |

| Max. Location Speed | 60m/min | |

| Laser Wavelength | 1070nm | |

| Minimum Line Width | ≤0.1mm | |

| Location Precision | ≤±0.05mm | |

| Re-Location Precision | ±0.02mm | |

| Max. Moving Speed | 100m/min | |

| Supporting Format | PLT, DXF, BMP, AI | |

| Power Demand | 380V/50Hz | |

| Cooling Way | Water Cooling | |

| Worktable Max. Load | 1000KGS | |

| Transmission Method | Ball Screw Transmission | |

| Table-Driven System | Japanese Imported Panasonic Servo Motor & Driving System | |

| Focus Method | Following and Automatic Adjust Focus | |

| Control Method | Offline Movement Control | |

| Control Software | Perfect Laser Professional Laser Cutting Software | |

Quick Details

Application: Laser Cutting

Condition: New, New

Laser Type: Fiber Laser

Applicable Material: Metal, carbon steel, silicon steel, stainless steel, aluminum, titanium

Cutting Thickness: 1-12 m (carbon steel)

Cutting Area: 2500*1300mm

Cutting Speed: 5-14m / Minute

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software:Perfect Laser Professional Laser Cutting Software

Graphic Format Supported: AI, BMP, DXF, PLT

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Certification: CE, ISO, FDA

After-sales Service Provided: Engineers available to service machinery overseas

Dimension(L*W*H): 4.62*2.8*2.2m

laser power: 200W

Max. Moving Speed: 100m/min

Warranty: 24 months

Transmission Method: Ball Screw/Gear Rack Transmission

Table-Driven System: Japanese Imported Panasonic Servo Motor & Driving System

location precision: ±0.05 mm

cooling system: water cooling

function: metal cutting