Detailed Product Description

| Model Number: | ACCURL-1515L CNC Water Jet Cutting Machine | Effective Cutting Area(Length): | 1500mm |

|---|---|---|---|

| Effective Cutting Area(width): | 1500mm | High Pressure System: | 380(4000Bar) |

| Main Motor: | Main Motor From Germany Siemens | Model: | ACCURL-2030L |

| Keywords: | Water Jet Machine Price |

Trade Assurance China manufacturer Anhui ACCURL water jet compound material cutting machine price

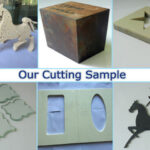

A high pressure water jet cutting machine is a tool which slices into metal and other materials, using a jet of water at high velocity and pressure. With the benefits of low noise, no pollution, high precision, and good reliability, our water jet cutting machine has found many applications in a variety of industries from mining, automobile, paper, and food, to art and architecture, where it is used to cut rubber, foam, plastic, composite, stone, tile, metal, marble, glass, etc.

Perfect Waterjet Cutting:

ACCURL® Waterjet machining is achieved by forcing a large volume of water under high pressure through a small orifice in the cutting nozzle. The accelerated steam of water leaving the nozzle impacts the material and starts the cutting process. Kerf from the accelerated stream of water is extremely narrow. This pressure is then concentrated in a small area on the material which starts to erode the material. Softer materials can be cut with water pressure. Harder materials require the use of an abrasive feed system, such as metal cutting. The abrasive is introduced into the high pressure water stream, which then starts the erosion of the harder materials. Although waterjet machining is the slowest cutting process, there are definite advantages that outweigh its' pace:

1. No Heat-Affected Zone

2. No Mechanical Stresses

3. Very Narrow Kerf

4. No need for Secondary Operations

5. Smooth Surface

Main Features

The fast, efficient, and precise ACCURL® Center provides top performance in waterjet machining of complex parts from many materials. From simple metals to complex composites, the 4’ 7” square cutting area of the proven is ideal for rapid prototyping and just-in-time manufacturing of small to medium-sized parts. With simple fixturing and easy access to the cutting table, setup times are significantly reduced, increasing productivity and profitability.

1. Fastest cutting speeds and best precision compared to any abrasivejet in the industry and is backed by our exclusive NAIKY PCIMC-6A® Software with real world cutting data

2. Programmable Motorized Z-Axis with a precision ACCURL® 5i Nozzle Assembly can boost cutting productivity and process efficiency

3. Tilt-A-Jet® taper compensating abrasivejet cutting head (available as an option)

4. Precision X-Y Axis rigidly mounted to the cutting table

5. Pre-loaded linear bearings and precision ball screws

6. Low maintenance, high reliability scissor-style hard plumbing

7. Drive system sealed against water, dirt, and grit

8. Easy operator access to the work area

9. High efficiency Generation 4 USA Hypertherm ® pump systems available in 30, 40, or 50 hp with operating efficiencies up to 90%

10. Robust and accurate design for tight tolerance cutting and reliable operation

11. Rapid Water Level Control for quiet and clean submerged cutting

12. Bulk Abrasive Delivery System transports garnet from the assembly’s large hopper into the Zero Downtime Hopper located on the Z-Axis

System

Hp System: WJPOWER-420 420(Fully Imported Configuration)

Max.Pressure: 420Mpa

Max.Flowrate: 3.7L/min

Electrical Power:37KW/50HP

Voltage: 220V~480V/50,60HZ.3PH

Intensifier assembly is fully imported from Accustream/Hypertherm

WEIHONG-V9 CNC SYSTEM

ITALY ECS-905 CNC CONTROLLER (OPTIONAL)

WEIHONG-V9 system is especial used for CNC waterjet cutting area,as to our years experience,this system can meet your most requirement,its features ai following:

Support G code generated from UG,MASTERCAM,AUTOCAD etc,DXF,PLT,ENG Format. Support advanced auto function of breakpoint memory and jump perform of program block.Small hole,small arc,corner deceleration pause function.

Support simulation function.

Support to display file process information,such as process time,path,process range.

Advantages of CNC controller

1. Industrial control computer: high reliability, convenient man-machine dialogue, real-time control of the cutting process

2. CNC control,19 inch LCD. facilitate operators to observe and reduce visual fatigue.

3. Appropriate height of operating desk, reasonable display angle, and 180-degree horizontal rotation for easy operation and viewing

4. Replace the relay with PLC, with a computer communications, flexible control

5. Professional waterjet cutting software, easy to operate , easy to learn, and practical.

6. DXF file ,can use AUTOCAD to produce DXF file

7. IPC and the professional software based on windows XP/7

Specification

| working table | mm | 2000 x 1000 | |

| X-axis | stroke | 2000 | 2000 |

| Speed | 0~15 | 0~15 | |

| Y-axis | stroke | 1000 | 1000 |

| Speed | 0~15 | 0~15 | |

| Z-axis | stroke | 150-180 | 150-180 |

| Speed | 0~12 | 0~12 | |

| Control accuracy | mm | ± 0.01 | |

| Positioning accuracy | mm | ± 0.02 | |

| High Pressure System | Max Pressure | 380 | 380 |

| Power | 37(50HP) | 37(50HP) | |

| Total electric power | KW | 38 | |

| Max load of working table | Kgs | 1000 | |

| Format supported | AI, PLT, DXF, etc | ||

| Machine weight | Kgs | 4350 | |

| Outside dimension | mm | 4050x2250x1850 | |

| Product Name | Water Jet Machine Price | ||