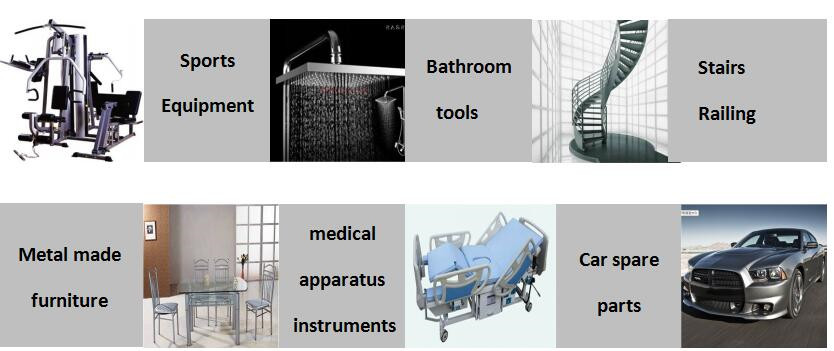

Applications

Application Materials

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries

ACCURL Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

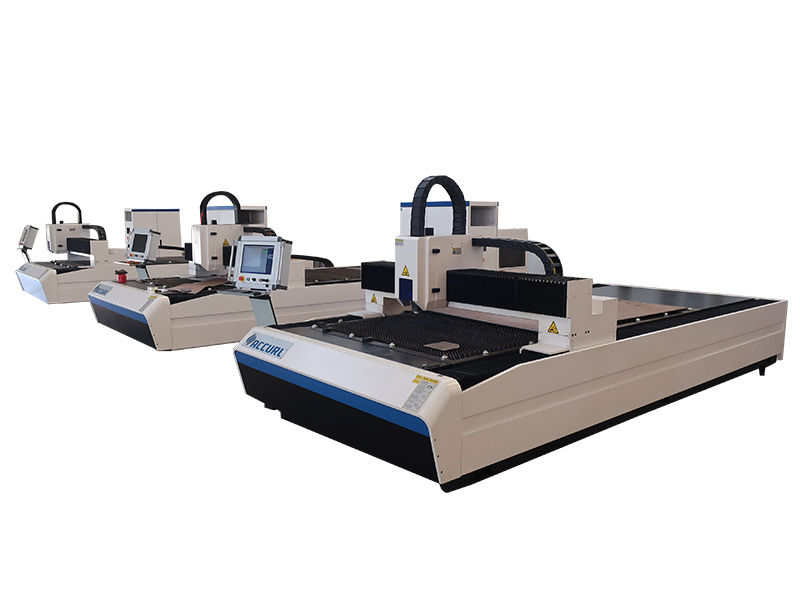

Product Description

• Characteristics

1. Low Cost:

Photoelectric conversion rate is higher than 30%, highly saving energy and thus protecting environment. The photoelectric conversion of fiber laser cutting machine is 3 times higher than CO2 laser cutting machine

2. Excellent Laser Beam Quality:

Fiber laser has smaller focus diameter and highER work efficiency, high accuracy and cutting quality.

3. High Cutting accuracy:

Positioning accuracy of fiber laser cutter is 0.05mm, repeat positioning accuracy of 0.03 mm.

4. Stable Running:

Adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

5. Excellent cutting effect:

Non-contact cutting make sure that the trimming is hardly affected by heat, therefore no thermal deformation of the workpiece, no need a second processing.

6. Saving materials:

The machine adopts Cypcut software. Using computer programming, you can cut different shapes of products, to maximize the utilization of materials.

7. Easy Operations:

Fber line transmission, no adjustment of optical path;

8. Super Flexible Optical Effects:

Compact design, compact and easy to flexible manufacturing requirements.

1. Machine bed

Stronger machine frame ensures a high capacity of loading and no easily deformation.

The cutting effect is highly guaranteed and the service time is longer.

2. Control system

With Cypcut Control system and software with English language, applicable insert files with DXF. Or AI format. Drawing in the software is also okay. Software with fly cutting mode for cutting same products for save time. With Nesting function, autonomic compose type for saving materials by saving spaces.

3. Fiber Laser source

Raycus 750W laser source

The photoelectric conversion more than 30%;

Working environment: 10-40 degree

Device with air-condition to keep it in normal temperature.

Lifetime:100000 hours

4. Driving system

Four sets of Japanese Panasonic drive motors.

Match-able with the transmission system, improve cutting speed and precision.

5. Gear Transmission

Gear- rack transmission system which with Taiwan Hiwin brand.

X and Y axis Moving speed can be max 80m/min.

6. Cooling system

When laser head cut metals, there will produce some hot energy in laser head and laser device. Water chiller is for cooling this two parts. Laser head part, mainly cooling the mirrors.

Temperature in the water chiller is auto adjustment, mainly set up with 25 degree around.

Water in chiller should be pure water.

Technical parameters

SPECIFICATIONS FOR LXF-1530 fiber laser cutting machine | |||

LASER SOURCE | RAYCUS LASER | ||

CUTTING HEAD | China domestic famous cutting head | ||

DRIVE MODE | Yaskawa stepper motor and driver | ||

TRANSMISSION | Gear transmission | ||

GUIDE RAIL | Hiwin square guide rails | ||

REDUCER | Imported from France | ||

WATER CHILLER | DOLUYO 1P | ||

CONTROL SYSTEM | CYPCUT from shanghai, China | ||

COMPUTER | ADVANTECH INDUSTRY COMPUTER | ||

POWER REQUIREMENT | 3 PHASE AC 380V 50HZ | ||

GROSS WEIGHT | 3.05MTS | ||

WORKING SIZE | 3000*1500 MM | ||

Quick Details

Application: Laser Cutting

Condition: New

Laser Type: Fiber Laser

Applicable Material: Metal

Cutting Thickness: 0-8mm carbon steel

Cutting Area: 1500*3000mm

Cutting Speed:50m/min

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: Cypcut control system

Graphic Format Supported: AI, DST, DWG, DXF, DXP, PLT

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: LXF-1530

Certification: CE, ISO

After-sales Service Provided: Engineers available to service machinery overseas

Laser power: 750W (Optional 300, 500w, 1kw)

Working area:1500mmX3000mm (W/L)

Fiber source: Raycus fiber source

Working voltage: 380v 50hz at 3 phases

Working Table: Sawtooth table

Driving system: Japanese YASKAWA servo motor

Repositioning resolution:±0.05mm/m

Axial positioning accuracy: ±0.04mm/m

Cooling system: Industrial water chiller 1.2P

Cutting head: China famous brand