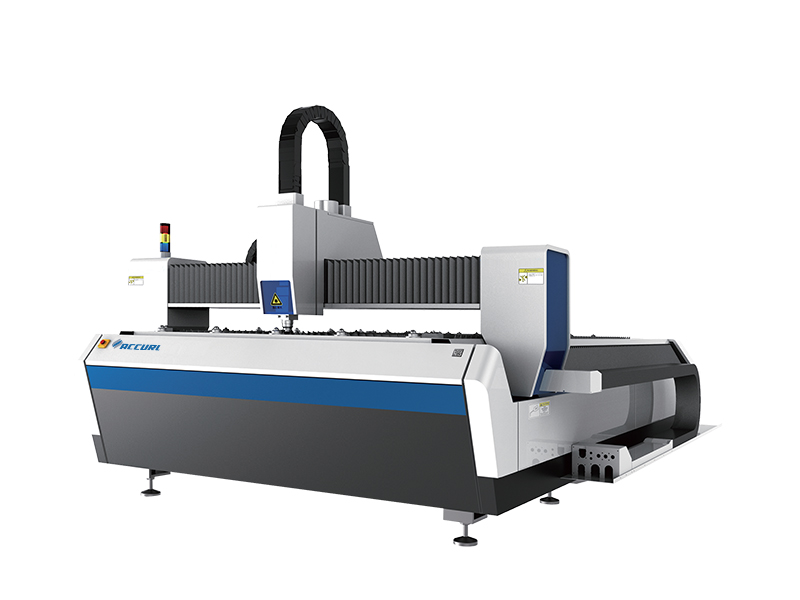

Detailed Product Description

| Model Number: | ECO-FIBER-1530-2KW ACCURL | Working Range: | 1500x3000mm |

|---|---|---|---|

| Laser Type: | USA IPG Fiber YLS-2KW | Linear Guide: | Taiwan HIWIN |

| Total Power Consumption: | Accurl Laser Professional Laser Cutting Software | Keywords: | Tube Laser Cutting Machine |

2000W Tube Laser Cutting Machine for Sheet Metal and Tube of Carbon steel 16mm

Product Description

The Accurl@ Fiber Lasers bring you a cost effective, low-maintenance, low operating cost,environmentally friendly solution to your organization. We deliver a machine that providesquality cutting and tolerances with small productivity loss between jobs, equating to higher returnon investments. Our fiber laser cutting machines are developed and sold based on these criteria.

1. Manufactured by people who use their own machines.

2. The resonator comes with a 100,000 hour warranty from the manufacturer (IPG)

3. Higher cutting speeds possible

4. Dual interchangeable tables allow for faster loading and unloading, reducing downtime

5. Laser wavelength is one-tenth of a CO2 laser

6. Reduction in cutting variables or tribal knowledge

7. Fiber Laser is extremely efficient, equates to very low power consumption

8. Low cost of operation, energy cost reduced, no laser gases requied to produce beam

9. High cutting flexibility (Steel, Stainless Steel, Brass, Copper, Titanium, Aluminum, and more)

10. Created and tested in a 100,000 sq ft Research and Development facility operating 9 metal cutting fiber Lasers, cutting 24/7.

Fiber Laser Tube Cutting Machine Features

1. Capacity up to O.D. 152 mm

2. Cutting Lengths up to 2000mm or 3000mm (longer lengths by request)

3. Wall thickness from 0.6 - 6.0mm (Mild Steel)

4. Automatic Bundle Loading System with Material Alignment

5. Automatic Unloading System with Conveyor

6. Equipped with 1.0 kW (Standard) or 2.0 kW (Optional) Laser Resonator

7. Multi-Axis CNC Controls with Touch Screen Interface

8. SOCO CAD-CAM system for Tubes and Profiles with built-in Nesting

9. SOCO i2 ( Intelligent interface) 3D operation software

STANDARD EQUIPMENT

1. 3 Axis (X, Y, Z)

2. FAGOR 8055 CNC control unit

3. Servo Motor

4. Auto - focus cutting head

5. Laser Source

6. Chiller Unit

7. Clean-dry air system

8. Safety Cabinet

9. Automatic-Dual Shuttle Table

10. CAD/CAM Software

11. Conveyor

12. Warning Lamp

13. Nozzle Set

14. Nozzle cleaning and height calibration table

OPTIONAL EQUIPMENT

1. Linear motor technology

2. IPG 0.5 kW, 1 kW, 2 kW, 3 kW, 4 kW and 6 kW laser source options

3. Extraction unit.

4. Light protection barrier

5. Pneumatic sheet support system for easy sliding

Standard Euipment

1. CUTTING TABLE

The dual cutting table system is designed for in-creasing your workflow and reducing time spent on placing and removing materials. Cutting table exchange speed can be adjusted according to thickness of materials.

2. NOZZLE CLEANER

Keeping your machine cutting quickly and cleanly is important. Our nozzle cleaner helps improve the life of your nozzles so your cuts stay consistent, longer.

Product Application

1. Applicable Fields

Applicable for high-speed cutting on various metal plates or tubes such as S/S, carbon steel, galvanized sheet,electrolytic plate, aluminum plate, steel, brass, alloy plate, rare metals and other materials;

2. Widely used

Widely used in kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and metal processing.

SPECIFICATIONS

| Model | ECO-FIBER 3015 / 2KW | |

| CNC Control Unit | FAGOR 8060 CNC System | |

| X axis (Rack & Pinion) | 3000 mm | |

| Y axis (Rack & Pinion) | 1500 mm | |

| Z axis (Ball Screw) | 100 mm | |

| Maximum cutting capacity | Mild steel | 16 mm |

| Stainless steel | 8 mm | |

| Aluminyum | 6 mm | |

| Work piece dimensions | 1525 x 3050 mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 2.5G (25m/s2) | |

| Vector speed | 148 m/min | |

| Absolute positioning accuracy | ± 0.08 mm | |

| Repeatability (X and Y axis) | ± 0.03 mm | |

| Max. load capacity | 2450 kg | |

| High Performance CNC System | FAGOR 8060 from Spain Brand | |

| Laser power | IPG YLS-2 kW from Germany | |

| High Performance Servo motor/drive | FAGOR from Spain Brand | |

| Laser Cutting Head | PRECITEC from Germany | |

| Motoreducer | STOBER from Germany | |