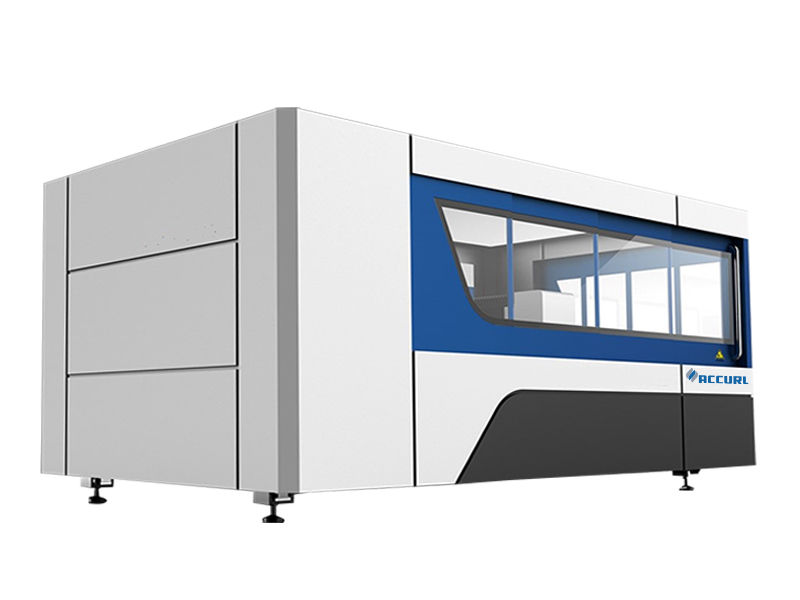

Features of Fiber Laser Cutting Machine

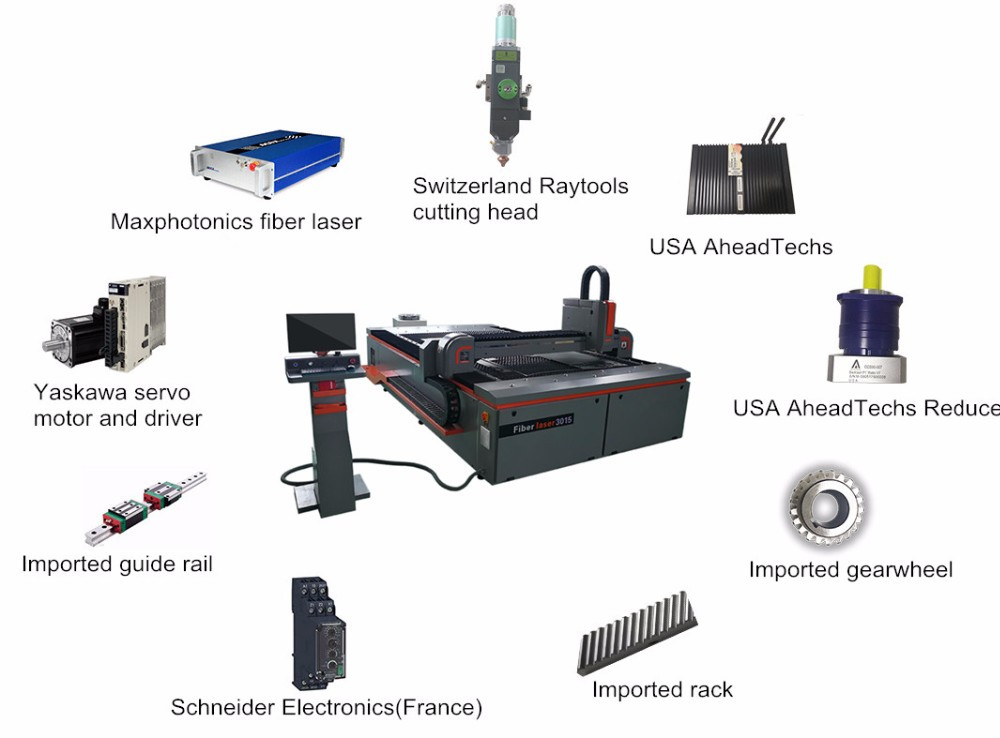

1.High quality cutting: Adopted Switzerland RAYTOOLS professional laser cutting head, to ensure the best cutting results.

2.Fiber laser source: adopted Maxphotonics laser source, which is the first domestic brand of the stable and reliable medium power laser source, have good performance;

3.Easy to operate: Adopted world’s leading technology EtherCAT bus USA cnc laser cutting system, very easy to operate;

4.Open gantry structure: Adopted bridge gantry structure, imported rack rail drive,and using centralized lubrication device, easy to maintain;

5.Stable and practical: Adopted reinforced welded bed, after the tempering treatment and vibration aging to eliminate stress, so the machine tool deformation can be controlled in ± 0.02mm;

6.Industrial aesthetic appearance design: The beam is made with drawing craft and the fine milling processing, it has light weight, high rigidity and good dynamic performance;

7.High efficiency and saving materials: The optical path of the whole machine is transmitted by optic fiber, External optical path is free maintenance, consumable consumes little.

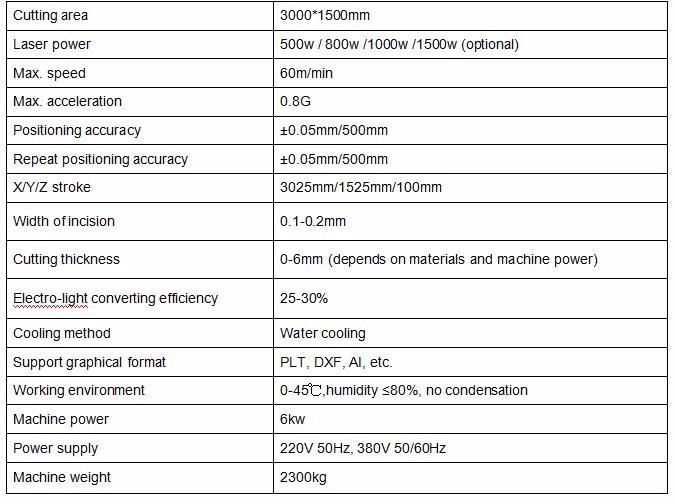

Technical Parameters of Fiber Laser Cutting Machine

Advantage of Fiber laser cutting machine

1. Excellent path quality: Smaller laser dot and high work efficiency, high quality.

2. High cutting speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7 Easy operations: fiber line transmission, no adjustment of optical path.

Application of Fiber Laser Cutting Machine

Suitable for carbon steel ,mild steel,SS ,aluminum alloy plate and copper plate and other metal.It is suitable for medium and thin thickness material processing.

Applied in sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automobile, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, sheet metal processing, kitchen utensils and appliances, craft gifts, tool processing, decoration, advertising, metal processing and other manufacturing industries.

Quick Details

Application: Laser Cutting

Condition New

Laser Type: Fiber Laser

Applicable Material: Metal, Stainless steel, carbon steel, iron

Cutting Thickness: 0-6mm

Cutting Area: 1500*3000mm

Cutting Speed: 0-60000mm/min

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: AHEADCUT, USA

Graphic Format Supported: DXF

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: MKC-3015-500

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Laser power: 500W / 800W / 1000W / 1500W

Laser source: Maxphotonics

Function: Metal Cutting

Laser wavelength: 1070-1080nm

Width of incision: 0.1-0.2mm

Position accuracy: ±0.05mm/500mm

Power supply: 220V 50/60Hz

Machine weight: About 2300kg

Machine size: 4500mm*2250mm*1700mm

Warranty: 1 Year