Detailed Product Description

| Model Number: | ECO-FIBER-1530-6KW ACCURL | Working Range: | 1500x3000mm |

|---|---|---|---|

| Laser Type: | USA NLIGHT Fiber YLS-6KW | Laser Head: | Swiss Raytools Auto-following |

| Table-driven System: | Japanese Yaskawa Servo Motor & Driving System | Keywords: | Fiber Laser Pipe And Tube Cutting Machine |

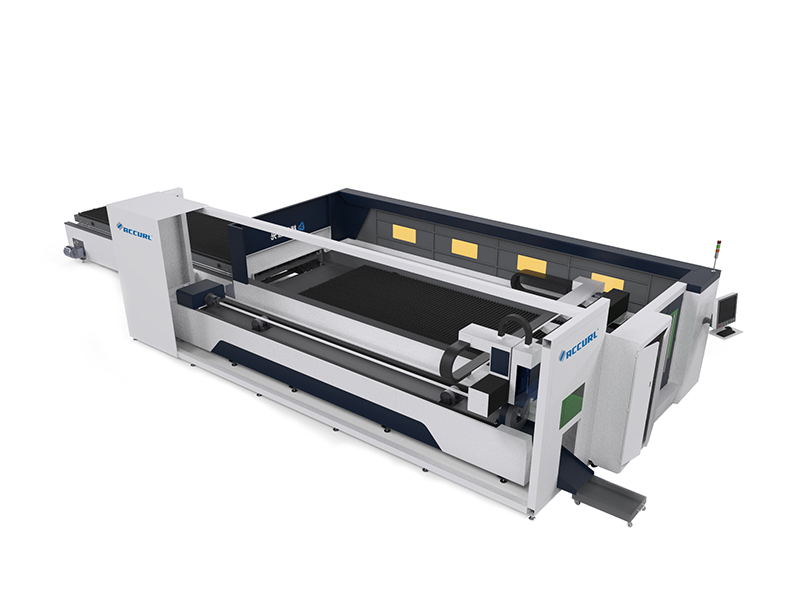

6000W CNC Fiber Laser Sheet Metal and Tube / Pipe Cutting Machine Made in China

Accurl’s introduces its newest generation in tubes and profiles processing technology – the Fiber Laser Tube Cutting System. With over 30 years of experience in design and manufacturing experience in tube cutting technology, Accurl is specialized in solutions for the Tube and Pipe industries, and the new Laser Tube Cutting Line is the ultimate solution for joining multiple machining processes in one system for maximum flexibility, automation and performance.

Main Features

The ACCURL@ Fiber Lasers bring a cost eᴀective, low-maintenance, low operating cost and environ-mentally friendly solution to your organization. Our ἀber laser machines provide quality cutting and tolerances with minimal productivity loss between jobs, equating to a higher re turn on investment.

1. Acceleration speed: 19,6 m/s2 (2G).

2. Maximum simultaneous positioning speed: 160m/min.

3. Precision: + - 0.05 mm.

4. Energy efficiency: greatly reduced power consumption.

5. Excellent cutting quality for fine thic kness and medium thickness sheet metals.

6. IPG Resonator. Power output from 1 kw to 6 kw .

7. Piercing Sensor.

8. Collection of work pieces and trimmings.

9. Dual proportional valve control system for different gas pressures and special system for high pressure cutting.

STANDARD EQUIPMENT

1. 3 Axis (X, Y, Z)

2. FAGOR 8055 CNC control unit

3. Automatic-Dual Shuttle Table

4. CAD/CAM Software

5. Conveyor

6. Warning Lamp

7. Nozzle Set

8. Nozzle cleaning and height calibration table

OPTIONAL EQUIPMENT

1. Linear motor technology

2. IPG 0.5 kW, 1 kW, 2 kW, 3 kW, 4 kW and 6 kW laser source options

3. Extraction unit.

4. Light protection barrier

5. Pneumatic sheet support system for easy sliding

Dual Function Fiber Laser Sheet Metal & Tube Cutting Machine Main Features

1. Open design provides easy loading and unloading.

2. Single working table saves space.

3. Drawer style tray makes easy collecting and cleaning for the scraps and small parts.

4. Integrated design provides dual cutting functions for sheet and tube.

5. Gantry double driving structure, high damping bed, good rigidity, high speed and acceleration.

6. The world’s leading fiber laser resonator and electronic components to ensure machine superior stability.

Product Features

1. High output power, 500-2000 watts is optional.

2. Can cut inclined truncation surface at the end of tubes.

3. Can cut intersection line of branch pipe, which is intersected with circular main pipe.

4. Can cut off square pipes and do 360 degree turning cutting.

5. Can cut square holes, waist type holes on tubes.

6. Can do various graphic cut on square tube, oval tube, U tube and rectangular tube etc.

Detailed Images

1. Machine Parts

Name: Machine Body

Brand: ACCURL

Original: CHINA

1. the steady gantry framework provides an open worktable.

2. Synchronous X/Y/Z axes: The Z-axis can run 150mm, suitable for cutting many varieties of metal sheets.

3. High quality guarantees its durability and easier maintenance

2. Conveyor System

Name: Conveyor System

Brand: ACCURL

Original: CHINA

A special hard steel construction conveyor system, standard on our machines, is located under the workspace. The conveyor removes slag and small parts during the cutting process. The operator can choose the movement direction of the conveyor.

3. Main Features

Name: SINGLE CABLE SERVO MOTOR TECHNOLOGY

Brand: YASKAWA

Original: Japan

1. Accurl has 4 servo motors for all axial movements.These are the latest technology single cable servomotors.

2. Power and process data are transmitted in onestandard motor cable, significantly reducing costs.

3. This technology also gives more accurate positioningand more geometrically accurate parts.

SPECIFICATIONS

| Model | ECO-FIBER 3015 / 6KW | |

| CNC Control Unit | FAGOR 8060 CNC System | |

| X axis (Rack & Pinion) | 3000 mm | |

| Y axis (Rack & Pinion) | 1500 mm | |

| Z axis (Ball Screw) | 100 mm | |

| Maximum cutting capacity | Mild stee | 32 mm |

| Stainless steel | 16 mm | |

| Aluminyum | 16 mm | |

| Work piece dimensions | 1525 x 3050 mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 2.5G (25m/s2) | |

| Vector speed | 148 m/min | |

| Absolute positioning accuracy | ± 0.08 mm | |

| Repeatability (X and Y axis) | ± 0.03 mm | |

| Max. load capacity | 2450 kg | |

| High Performance CNC System | FAGOR 8060 from Spain Brand | |

| Laser power | IPG YLS-6 kW from Germany | |

| High Performance Servo motor/drive | FAGOR from Spain Brand | |

| Laser Cutting Head | PRECITEC from Germany | |

| Motoreducer | STOBER from Germany | |