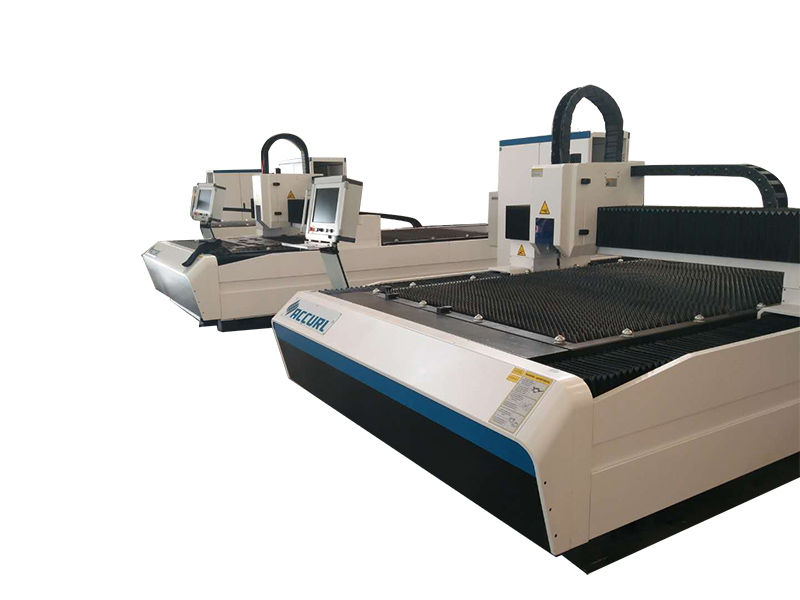

Detailed Product Description

| Model Number: | ECO-FIBER 3015 / 2KW ACCURL | Working Range: | 1500x3000mm |

|---|---|---|---|

| CNC Control Unit: | FAGOR 8060 CNC System | Maximum Cutting Capacity: | 16 Mm Mild Steel |

| Work Piece Dimensions: | 1525 X 3050 Mm | Product Name: | CNC Laser Cutting Machine |

Product Advantages

1. High Efficiency--The rapid cutting speed is two times higher than ordinary laser cutting machine.

2. Environment friendly--Laser cutting will not creates any gases for the special cutting technology for steel sheet.

3. Lower Consumption--The power consumption of our fiber laser cutter was reduced by 20%-30% compared wtih ordinary laser cutting machine.

4. Maintenance-free--For the fiber laser cutter, the reflect lens are no needed. It will help to save a lot of time when optical path is adjusted. The laser generator with longer lifetime which no need maintaince during usage

Machine Features

1. High performance.fiber transmission can make sure the same quality cutting effect in every point of the material.

2. High efficiency,fast cutting speed.photoelectric conversion rate about 35%.

3. Low gas consumption.it has the cutting technology specially for steel board and produce no gas when cutting .

4. Low power consumption .environment -friendly and energy -saving,reduce 20%-30% power compard with co2 cutting machine.

5. Maintenance-free ,fiber transmision without reflection lens,can save time in light path adjustment .fiber exerts its features better in thin metal sheet cutting.

Fiber laser cutting Machine application field

Widly applied to metal-sheet processing, stainless steel decorative engineering, advertising trademark and advertising character, high/low voltage electrical cabinet, kitchenware, metal crafwork, auto parts, farm machinery, medical instrument, sports equipment,environmental protecion equipment, elvvator apparatus, central air conditioning, metal craftwork, hardeware, tool and gauge etc...

Standard Equipment:

•FAGOR 8060 CNC Controller

•IPG YLS-3000W Ytterbium Laser Resonator

•Automatic Double Pallet Changer(Shuttle Table)

• Precision Rack & Pinion Drive System (Made in Germany)

• Radan or Lantek CAD/CAM system

• Light source

• Chiller

• 3 lower protective lenses

• 3 Ceramic Nozzle Adapters

• Auto-calibrated nozzle system

• Lens with 5.9” Focus Length

• Smart Slag Collection System/ Chip Conveyor

• Fiber Beam Transmission System (Fiber Cable)

• Operates with both N2 and O2 (cutting) gases

• Home Position Alignment System

• Auxiliary Gas Selector

• Auto Reflection Warning

• Working Lights

• 5 Nozzles each of the Following: (1.0mm, 1.2mm,1.5mm, 2.0mm , 2.5mm , 3.0mm)

Specification

| Model | ECO-FIBER 3015 / 2KW | |

| CNC Control Unit | FAGOR 8060 CNC System | |

| X axis (Rack & Pinion) | 3000 mm | |

| Y axis (Rack & Pinion) | 1500 mm | |

| Z axis (Ball Screw) | 100 mm | |

| Maximum cutting capacity | Mild steel | 16 mm |

| Stainless steel | 8 mm | |

| Aluminyum | 6 mm | |

| Work piece dimensions | 1525 x 3050 mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 2.5G (25m/s2) | |

| Vector speed | 148 m/min | |

| Absolute positioning accuracy | ± 0.08 mm | |

| Repeatability (X and Y axis) | ± 0.03 mm | |

| Max. load capacity | 2450 kg | |

| High Performance CNC System | FAGOR 8060 from Spain Brand | |

| Laser power | IPG YLS-2 kW from Germany | |

| High Performance Servo motor/drive | FAGOR from Spain Brand | |

| Laser Cutting Head | PRECITEC from Germany | |

| Motoreducer | STOBER from Germany | |

| Product Name | CNC Laser Cutting Machine | |