Metal Sheet 3D True Hole CNC Plasma Bevel Cutting Machine

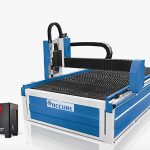

CNC Micro Edge PRO Plasma Cutting Machine is one of our most popular machines.

We are professional manufacturer of CNC plasma and flame cutting machine.

Our CNC system contain Hypertherm Micro EDGE PRO, EDGE PRO, SJTU-SK, HC6500, etc.

All the above cutting machines have plasma and oxy-fuel flame options.

Our main products are: CNC Plasma Cutting Machine, CNC Flame Cutting Machine, CNC Oxy-fuel Cutting Machine, CNC Plasma Cutter, CNC Flame Cutter, CNC Plate Cutting Machine, CNC Cutting Machine, CNC Pipe Cutting Machine, CNC Profile Cutting Machine, CNC Pipe Cutter, CNC Plate Cutter, Oxy-fuel Cutting Machine, Cutting Table, Gantry Type Cutting Machine, pipe fixed-length cutting machine, CNC bevel cutting machine, CNC pipe beveling machine, Micro EDGE PRO System Cutting Machine, etc.

Plasma: Hypertherm, Thermal Dynamics, Kjellberg, Tayor LGK, ESAB, etc,

| CNCTG series cutting table |

| Economical and Practical |

| Good finish surface, almost no secondary treatment |

| Simple to use |

| No need more foundation preparation, space saving |

| Split-type designing, Facilitate loading and transport |

| G code and M code recognizable |

| CNCTMG series cutting table |

| High speed and precision |

| Compact and integral structure |

| Precision linear guide driving |

| Great finish surface, dispense with secondary treatment |

| Excellent running stability and higher precision cutting ability |

| G Code and M code recognizable |

| CNCDG/CNCSG series gantry type cutting machine |

| Heavy-duty and Durable |

| CNC Oxy-fuel and plasma cutting torch |

| Beveling and strip cutting torch |

| Integrated auto-ignition with automatic height controller |

| Various optional items, expand machine capacity |

| G code and M code recognizable |

| CNCXG series pipe cutting machine |

| Efficiency and flexible |

| 3D Cutting and beveling |

| Oxy-fuel and Plasma cutting module |

| Touch screen panel, convenient and fast data inputting |

| Compatible with Steel Structure design software |

| Maximum cutting pipe diameter 1500mm |

Gantry Type CNC Plasma And Flame Cutting Machine

Gantry and box type welded structure, annealed, long service life, steady and durable under heavy load and high duty cycle condition.

Gapless gearing transmit, stable and smooth running in high speed, so that we can achieve excellent cutting quality.

Integrated auto-ignition with automatic height controller, keep the proper height between cutting torch and work piece, so that we can achieve the best cutting quality.

Able to cut work piece with several torches at the same time, can improve cutting efficiency

Low use and maintenance cost, dispensing special maintenance, friendly operator interface, easy to learn

Reliable, safe cnc system, automatic programming, optimization nesting and piercing path, so that we can save steel effectively

Optional items:

Powder marking device

Straight line stripe cutting torch

Straight line triple beveling torch

Rotary triple flame curve beveling torch

Rotary plasma curve beveling torch

Blow and draft dust and fume collection system

Water surface and underwater cutting table

| Cutting Technical Data | |||||||

| Model | CNCSG3000 | CNCSG3500 | CNCSG4000 | CNCSG5000 | CNCSG6000 | CNCSG7000 | CNCSG8000 |

| Effective Cutting Width (mm) | 2200 | 2700 | 3200 | 4200 | 5200 | 6200 | 7200 |

| Track Width (mm) | 3000 | 3500 | 4000 | 5000 | 6000 | 7000 | 8000 |

| Effective Cutting Length (m) | 2m less than track length | ||||||

| Cutting Thickness(mm) | Flame:5-120(Max 300mm) Plasma:1-80 | ||||||

| Basic components | |||||||

| Cutting Mode | Plasma and Oxy-Fuel/Flame | ||||||

| Drive Mode | Servo motor, Dual-drive | ||||||

| Cutting Torch Number | Customization | ||||||

| Driving Motor | Panasonic/Yaskawa | ||||||

| CNC Controller | Hypertherm EDGE Pro/Micro EDGE Pro, LKNC-3200, SJTU-SK, Burny | ||||||

| Available Plasma Power | Hypertherm, Kjellberg, Thermal Dynamics, ESAB | ||||||

| Programming software | Fastcam, SmartNest, Hypertherm | ||||||

| Supply power voltage | 3×380V±10% 50HZ/according to user's local condition | ||||||

| Operation language | Multilanguage | ||||||