Information

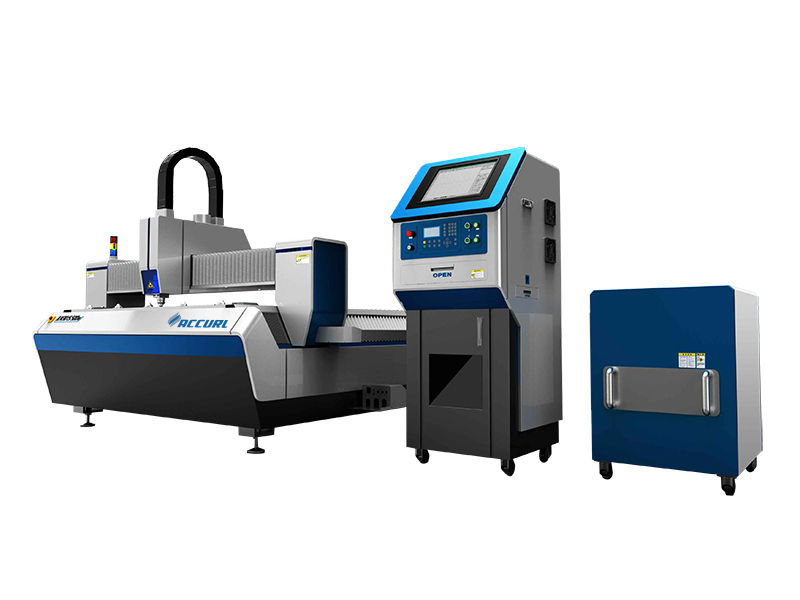

Fiber laser cutting machine is designed for cutting of the laser equipment, applicable to all types of metal (including precious metal), plating materials, coating materials, coating material and sheet cutting. Stable and reliable operation of the equipment, processing good quality, high efficiency, simple operation and easy maintenance.

Fiber laser cutting machine with the advantages of proportional valve:

☆Gas components imported from Germany Rexroth, AirTac and so on

☆Flexible: nitrogen, oxygen, air free choice

☆Low pressure cutting pressure is automatically controlled by the proportional valve

☆ Help improve the cutting process and high-quality cutting quality

☆ Special processing capacity: iron angle / thick plate holes

☆Reduce the manual adjustment work, improve production efficiency 30% to 50%

☆ Save 20% to 40% gas consumption

Fiber Laser Cutting Machine Advantage

(1) Fiber laser cutting machine is for metal precise cutting powered by fiber laser technology. The quality fiber laser beam results in faster cutting speeds and higher quality cuts compared to other cutting solutions. The key advantage of a fiber laser is its short beam wavelength (1,064nm). The wavelength, which is ten times lower than that of C02 laser, generates high absorption into metals. This makes the fiber laser become a perfect tool for cutting metal sheets of stainless steel, carbon steel, mild steel, aluminum, brass, etc.

(2) The efficiency of a fiber laser far exceeds traditional YAG or CO2 laser. The fiber laser beam is capable of cutting reflective metals with much less energy as the laser is absorbed into the metal being cut. The unit will consume little to no energy when not active.

(3) Another advantage of fiber laser is the use of highly reliable single emitter diodes with projected lifetimes greater than 100,000 hours of continuous or pulsed operation.

(4) ACCURL Laser software allows for the capability to control power, modulation rate, pulse width and pulse shape giving the user full control of the lasers capabilities.

Specification

| Laser power | 750W |

| Processing range | 3000mm*1500mm |

| X-axis stroke | 3050mm |

| Y-axis stroke | 1530mm |

| Z-axis stroke | 100mm |

| X/Y-axis positioning accuracy | ±0.03mm /m |

| X/Y-axis worktable repeating positioning accuracy | ±0.02mm |

| X, y axis max. linkage speed | 110m/min |

| Max. acceleration | 1.2G |

| weight | 4800Kg |

| The workbench max. load | 400Kg |

| The whole machine covers an area of | 4800mm*4800mm |

| Main power supply protection rating | IP54 |

| Cooling | Water cooling |

Basic Info

Model NO.: HF3015A

Laser Technology: Laser Control Fault Cutting

Driving Mode: Gear and Rack

Control Software: Fscut

Machine Power Supply: 380V, 50Hz/Three Phase

Laser Type: Fiber Laser

Max. Accelerated: 1.2g

Laser Source: Laser Source

Cutting Thickness: S/S 0-10mm

IP Degree: IP54

Servo Motor: Import

Positioning Speed: 110m/Min

Trademark: ACCURL

Transport Package: Exporting Standard Package

Specification: About4.8t

Origin: Anhui, China

HS Code: 8456100090