Product Description

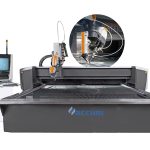

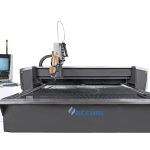

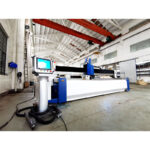

One full set of water jet cutting machine consists of cnc controller,worktable ,pump ,abrasive delivery system ,cooler.

other optionals : chiller ,sullage removal system, water soften unit.

WATERJET HIGH PRESSURE PUMP

Main feature:

Control:PLC

Shifting:electro-hydraulic control

Cooling:cooler/oil heat exchanger

In let water filter accuracy:≤0.45μm

Oil-return filter accuracy:20 μm

Working temp:0-60°c

Outlet:UNF 3/8"

Cooling in/out-let:NPT1"

pressurize :intensifier type

weight :1200kgs

CBM:3.5M3

Related Products

1,water jet cutting machine(3 axis)

2,Dynamic 5 axis waterjet machine

(marble granite tile design)

3,MAX series 5 axis waterjet cutting machine

(bevel cutting 0-±45°)

Our Services

One year guarantee:

Guarantee that machine is new advanced and no defect of material and technologic.

- Guarantee that technical date is integrated clean and right, also satisfy the requests of installation debugging test operation and maintenance.

- Guarantee that provide technical service and training in time.

Quick Details

Condition: New

Type: Stone Cutting Machine

Use: Marble

Production Capacity: marble ceramic granite tile

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: L1515/2015/3015/3020/4020

Voltage:380/220/400V ,3PH

Power(W): 30/37KW

Dimension(L*W*H): as to model

Weight:3000-7000kgs

Certification: CE ,ISO

Warranty: 1year

After-sales Service Provided: Engineers available to service machinery overseas

Machine name: water jet cutting machine used for non metal cutting with 3D bevel

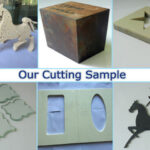

Cutting materials: Stainless steel , brass, aluminum, stone ,plastic ,glass.etc

power: 30KW/37KW,40/50HP

High pressure: 300-400mpa

Cutting accuracy: +/-0.1mm

Max.flowrate: 3.7 L/Min

abrasive name: garnet

accumulator ca.: 1Liters

drive system: AC servo and screw ,guideway

Intensifier Assembly: Hypertherm(Accustream), KMT(H2

CNC Water Jet Cutting Machines (Gantry /Cantilever type) (General technical characteriestics) | ||||||||

| Table Model (as to ask) | Unit | YC-L2015 | YC-L2515 | YC-L3015 | YC-L3020 | YC-L4020 | YC-L4030 | YC-X1520 |

| Cutting area | mm | 2000 * 1500 | 2500 * 1500 | 3000 * 1500 | 3000 * 2000 | 4000 * 2000 | 4000 * 3000 | 1500 * 2000 |

| Cutting accuracy | mm | +/- 0.1 | +/- 0.1 | +/- 0.1 | +/- 0.1 | +/- 0.1 | +/- 0.1 | +/- 0.1 |

| Positioning accuracy | mm | +/- 0.05 | +/- 0.05 | +/- 0.05 | +/- 0.05 | +/- 0.05 | +/- 0.05 | +/- 0.05 |

| Repeatability | mm | 0,025 | 0,025 | 0,025 | 0,025 | 0,025 | 0,025 | 0,025 |

| X,Y dry-run speed | m/min | 0-15 | ||||||

| Cutting speed | m/min | (as to detail material and thickness) | ||||||

| Motion for X.Y | HIWIN/TBI ballscrew and guideway ,mitsubishi servo motor to drive | |||||||

| Materials to cut | Copper ,steel ,rubber ,marble ,granite ,plastic ,glass ,aluminium etc (almost all kinds),thickness 0-120mm | |||||||

| Supply condition | Air ,water ,electricity ,abrasive(garnet),hydraulic oil | |||||||

| Max pump pressure | mPa | 380/ 410 | 380/ 410 | 380/ 410 | 380/ 410 | 380/ 410 | 380/ 410 | 380/ 410 |

| Power | kW/ hp | 30-37/ 40- 50 | 30-37/ 40-50 | 30-37/ 40-50 | 30-37/ 40- 50 | 30-37/ 40- 50 | 30-37/ 40-50 | 30-37/ 40-50 |

| Control by | Siemens | LOGO! | LOGO! | LOGO! | LOGO! | LOGO! | LOGO! | LOGO! |

| Inlet water supply: | mpa | >0.4 | >0.4 | >0.4 | >0.4 | >0.4 | >0.4 | >0.4 |

| Software | Shanghai NAIKY software (NC STUDIO) / MITSUBISHI servo drive / ADVANTECH industrial computer | |||||||

| Machine Power (can be customized) | V (3ph,50/60hz) | 220/ 380/415 | 220/ 380/415 | 220/ 380/415 | 220/ 380/415 | 220/ 380/415 | 220/ 380/415 | 220/ 380/415 |