Detailed Product Description

| Model Number: | ECO-FIBER-1530-2KW ACCURL | Working Range: | 1500x3000mm |

|---|---|---|---|

| Laser Type: | USA IPG Fiber YLS-2KW | Linear Guide: | Taiwan HIWIN |

| Transmission: | Taiwan YYC Gear And Rack | Keywords: | Metal Tube Fiber Laser Cutting Machine |

Metal Tube Fiber Laser Cutting Machine 2000W Price for 8mm Stainless steel

Product Description

The ACCURL Fiber Lasers bring a cost effective, low-maintenance, low operating cost and environmentally

friendly solution to your organization. Our fiber laser machines provide quality cutting and tolerances with minimal productivity loss between jobs, equating to a higher return on investment.

1. Manufactured by people who use their own machines

2. Laser beam transmitted through a fiber optic cable rather than with mirrors and channel tubing resulting in negligible power loss.

3. The laser light source has a life expectancy of more than three times that of an equivalent CO2 laser.

4. Higher cutting speeds possible

5. Dual interchangeable tables allow for faster loading and unloading, reducing downtime

Fiber Laser Tube Cutting Machine Features

1. Capacity up to O.D. 152 mm

2. Cutting Lengths up to 2000mm or 3000mm (longer lengths by request)

3. Wall thickness from 0.6 - 6.0mm (Mild Steel)

4. Automatic Bundle Loading System with Material Alignment

5. Automatic Unloading System with Conveyor

6. Equipped with 1.0 kW (Standard) or 2.0 kW (Optional) Laser Resonator

7. Multi-Axis CNC Controls with Touch Screen Interface

8. SOCO CAD-CAM system for Tubes and Profiles with built-in Nesting

9. SOCO i2 ( Intelligent interface) 3D operation software

10. Cutting for round, square, rectangle and various profile shapes

STANDARD EQUIPMENT

1. 3 Axis (X, Y, Z)

2. FAGOR 8055 CNC control unit

3. Servo Motor

4. Auto - focus cutting head

5. Laser Source

6. Chiller Unit

7. Clean-dry air system

8. Safety Cabinet

9. Automatic-Dual Shuttle Table

10. CAD/CAM Software

11. Conveyor

OPTIONAL EQUIPMENT

1. Linear motor technology

2. IPG 0.5 kW, 1 kW, 2 kW, 3 kW, 4 kW and 6 kW laser source options

3. Automatic sheet loading system

4. Momentum Gen-3 G Force

5. Full Automatic sheet loading – unloading system (TOWER)

Packing & Delivery

1. Our wooden case is after fumigation treatment.Needn’t timber inspection,saving shipping time.

2. All the spare parts of the machine were covered by soms softmaterials,mainly using pearl wool.

3. The outmost is wooben case with fixed formwork.

4. The botton of the wooden case has firm iron jack,covenient to hading and transport.

Detailed Images

1. Machine Parts

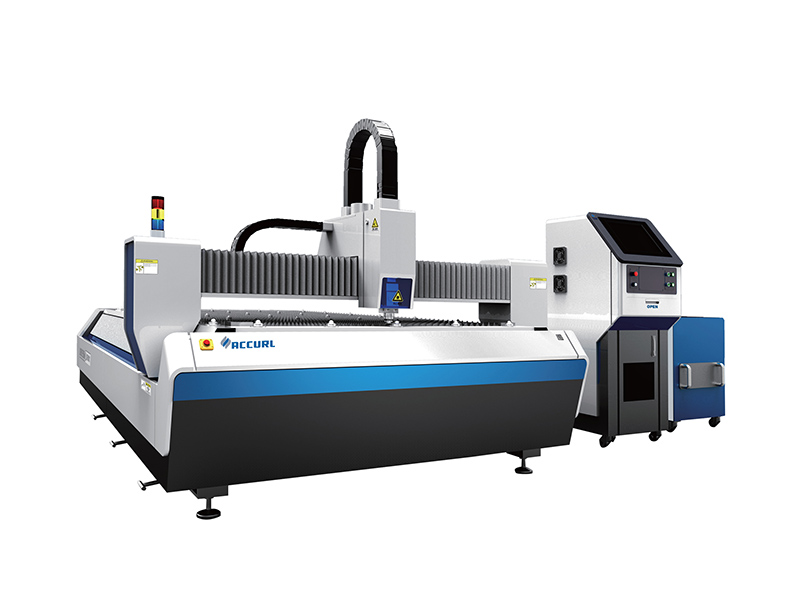

Name: Machine Body

Brand: ACCURL

Original: CHINA

1. the steady gantry framework provides an open worktable.

2. Synchronous X/Y/Z axes: The Z-axis can run 150mm, suitable for cutting many varieties of metal sheets.

3. High quality guarantees its durability and easier maintenance

2. Conveyor System

Name: Conveyor System

Brand: ACCURL

Original: CHINA

A special hard steel construction conveyor system, standard on our machines, is located under the workspace. The conveyor removes slag and small parts during the cutting process. The operator can choose the movement direction of the conveyor.

3. Main Features

Name: SINGLE CABLE SERVO MOTOR TECHNOLOGY

Brand: YASKAWA

Original: Japan

1.Accurl has 4 servo motors for all axial movements.These are the latest technology single cable servomotors.

2.Power and process data are transmitted in onestandard motor cable, significantly reducing costs.

3.This technology also gives more accurate positioningand more geometrically accurate parts.

SPECIFICATIONS

| Model | ECO-FIBER 3015 / 2KW | |

| CNC Control Unit | FAGOR 8060 CNC System | |

| X axis (Rack & Pinion) | 3000 mm | |

| Y axis (Rack & Pinion) | 1500 mm | |

| Z axis (Ball Screw) | 100 mm | |

| Maximum cutting capacity | Mild steel | 16 mm |

| Stainless steel | 8 mm | |

| Aluminyum | 6 mm | |

| Work piece dimensions | 1525 x 3050 mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 2.5G (25m/s2) | |

| Vector speed | 148 m/min | |

| Absolute positioning accuracy | ± 0.08 mm | |

| Repeatability (X and Y axis) | ± 0.03 mm | |

| Max. load capacity | 2450 kg | |

| High Performance CNC System | FAGOR 8060 from Spain Brand | |

| Laser power | IPG YLS-2 kW from Germany | |

| High Performance Servo motor/drive | FAGOR from Spain Brand | |

| Laser Cutting Head | PRECITEC from Germany | |

| Motoreducer | STOBER from Germany | |