Detailed Product Description

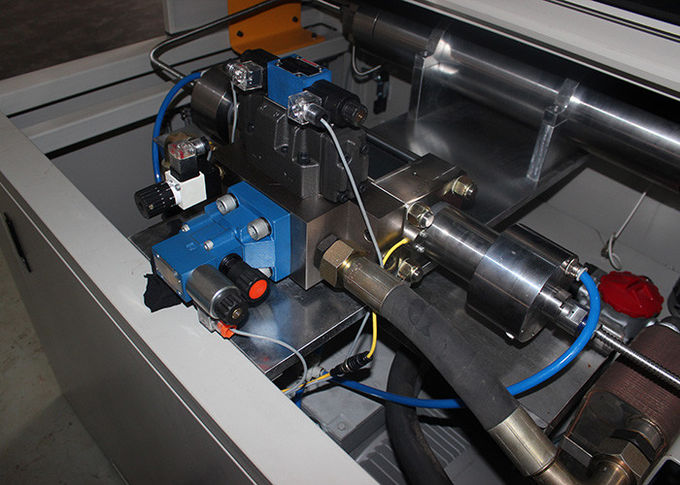

| Model Number: | accurl-1515L CNC Water Jet Cutting Machine | Effective Cutting Area(Length): | 1500mm |

|---|---|---|---|

| Effective Cutting Area(width): | 1500mm | Surface Roughness: | Ra≤25μm |

| Valve: | Valve From Germany Bosch-Rexroth | Keywords: | Water Jet Cutter For Stone |

Marble mosaic cutting machine China ACCURL water jet cutter for synthetic stone turquoise

Product Description

The ACCURL abrasive waterjet machine is a high-pressure waterjet machine that utilizes straight water cutting or abrasive waterjet cutting to cut several types of material. The ACCURL Water-Jet is a heavy-duty precision, ground ball screw designed system for maximum precision and rigidity.

Perfect Waterjet Cutting:

ACCURL® Waterjet machining is achieved by forcing a large volume of water under high pressure through a small orifice in the cutting nozzle. The accelerated steam of water leaving the nozzle impacts the material and starts the cutting process. Kerf from the accelerated stream of water is extremely narrow. This pressure is then concentrated in a small area on the material which starts to erode the material. Softer materials can be cut with water pressure. Harder materials require the use of an abrasive feed system, such as metal cutting. The abrasive is introduced into the high pressure water stream, which then starts the erosion of the harder materials. Although waterjet machining is the slowest cutting process, there are definite advantages that outweigh its' pace:

1. No Heat-Affected Zone

2. No Mechanical Stresses

3. Very Narrow Kerf

4. No need for Secondary Operations

5. Smooth Surface

6. Can Cut Various Materials

Main Features

1. Can be transfer the drawing to cutting quickly

2. Quick position-some or few fixing equipments

3. Hing accuracy-reduce the recutting

4. Quicker cutting speed

5. In no need of fabrication for the working parts

6. Safer for the operator and circumstance osteam,dust,smog etc

7. Cool cutting-no heat will be prouduced

8. Clear processing,in no need of clear the working parts again

9. Good cutting finishes-in no need of trimina the cutting finishes again

10. Narrow cutting gap

11. Quick calibration and easier versatility way of cutting. It has been proved that it can be used in mass production in the ideal system

12. Fit for CAD/CAW software

13. Waterjet cutting machine can cut almost all the materials.It can cut the foilat the thickness of 200mm

System

Hp System: WJPOWER-420D(Dual-intensifier HP System)

Max.Pressure: 420Mpa

Max.Flowrate: 7.4L/min

Electrical Power: 75KW/100HP

Voltage: 220V~480V/50,60HZ.3PH

Intensifier assembly is fully imported from KMT(H20 USA)

characteristic

1. Functional characteristic

1. The cutter head inclined at an angle in any direction,eliminating the phenomenon f concave convex and uneven cutting surface(to eliminate phenomenon of small surface and large bottom).To make the front junction smaller, reduce grinding link,can tile diretly.Reducing the polished and the production cost greatly.

2. Make the complex graphics more delicate and beautiful.

3. It turning without pause,no turning dot,make cutting speed faster.The cutting surface roughness wil not affect the collage.

2. Processing characteristic

1. CNC forming complex patterns.

2. Environmental pollution,no toxic gases and dust.

3. Can process a variety of high hardness material ,such as :glass,ceramics,stainless steel,or relatively soft material ,leather,rubber,diapers,etc.

4. Cutting smooth,no slag,doesn't need secondary processing.

5. Save the cost.

The advantages of water jet cutting machine

1. Can be transfer the drawings to cutting quickly

2. Quick position: some or few fixing quipments

3. High accuracy: reduce the recutting

4. Quicker cutting speed

5. In no need of fabrication for the working parts

6. Safer for the operator and circumstance: no steam, dust, smog, etc

7. Cool cutting: no heat will be produced

8. Clear processing: in no need of clear the working parts again

9. Good cutting finishes: in no need of rework the cutting finishes again.

10. Narrow cutting gap

11. Quick calibration and easier versatility way of cutting. It has been proved that it can be used in mass production in the ideal system

12. Fit for CAD/CAM software

13. Waterjet cutting machine can cut almost all the materials

Specification

| Model | accurl-4020L | ||

| working table | mm | 3000 x 1500 | |

| X-axis | stroke | 2000 | 3000 |

| Speed | 0~15 | 0~15 | |

| Y-axis | stroke | 1000 | 1500 |

| Speed | 0~15 | 0~15 | |

| Z-axis | stroke | 150-180 | 150-180 |

| Speed | 0~12 | 0~12 | |

| Control accuracy | mm | ± 0.01 | |

| Positioning accuracy | mm | ± 0.02 | |

| High Pressure System | Max Pressure | 380 | 380 |

| Power | 37(50HP) | 37(50HP) | |

| Total electric power | KW | 38 | |

| Max load of working table | Kgs | 1000 | |

| Format supported | AI, PLT, DXF, etc | ||

| Machine weight | Kgs | 5650 | |

| Outside dimension | mm | 4050x2250x1850 | |

| Product Name | Water Jet Cutter for Stone | ||