Product Description

Product Application:

Furniture ,Medical Device,Fitness Equipment,Oil Exploration,Display Shelf,Farm Machinery,Bridge,Boating,Structure Parts.

Applicable type for tube:

Specially for round,square,rectangular,oval,waist round tube and other metal pipes

Applicable Material:

Carbon Steel, Stainless Steel, Aluminum, Brass,Copper,Galvanized Steel.

Automatic Bundle Loader Steel Square Pipe Making Machine | |||

Pipe type | round, square, rectangular, oval, OB-type, C-type, D-type, triangle, etc (standard),Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) | ||

Pipe length | 6000mm | ||

Pipe size | Φ20-200mm | ||

Repeat position accuracy | ±0.03mm | ||

Position accuracy | ±0.05mm | ||

Fiber laser source | 1000w/1200w/2000w/2500w/3000w | ||

Position speed | Max 90m/min | ||

Chuck rotate speed | Max 105r/min | ||

Acceleration | 1.2g | ||

Cut Acceleration | 1g | ||

Bundle size | 800mm*800mm*6000mm | ||

Bundle weight | Max 2500kg | ||

Electric power supply | AC380V 50/60Hz 3PH | ||

Main Features

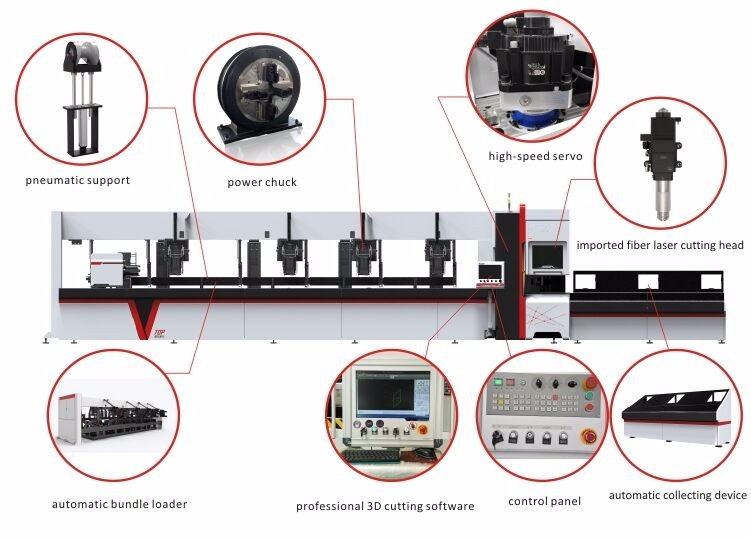

AUTOMATIC BUNDLE LOADER SYSTEM

1,Round pipe, rectangular pipe and other pipes can be fully automated loading, without human intervention. Other shapes pipe can be semi-automatic feeding artificially

2,Max loading bundle 800x800mm

3,Max loading bundle weight 2500kg

4,The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers

5,The tape support frame for easy removal

6,Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport

7,The pneumatic system components used AirTAC or other more high-end brand, PLC control, sensors and other selected Omron, Schneider and other well-known brands. Ensure the stability of the system and export standard

Detailed

Machine Parts

Name: Automatic loading mechanism

1.The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers

2.Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport

Machine Parts

Name: Automatic collecting device

1.Automatic elevating support, receive tube and scrap into the basket

2.Visual scale support can adjust support diameter quickly according to pipe diameter

3.Visual scale adjustable support lifting device saves feeding time, ensures concentricity, prevents pipe swinging

Main Features

Name: Power chuck

1.Chuck by changing the gas path, the usual four-jaw chuck linkage, optimization Cheng stroke power chuck double acting.

2.Cutting different diameters, the shape of the pipe in the travel range (bilateral stroke 80mm),no need to adjust the jaw easy setup and centered.

3.easy switching of different diameters, a substantial saving setup time..

Machine Parts

Name: Pneumatic support

The cutting of pipes of different diameters, by adjustable support system to quickly and accurately find concentricity pipe and claw, to achieve rapid feeding, care feeding purposes, saving setup time cut-out.You can assist chuck support, reducing the swing pipe..

Main Features

Name: Integration bed

1.As a whole plate welded bed, the whole length of 8 meters.

2.Integration bed can better ensure concentricity of equipment, vertical, precision installation fast and efficient.

3.The whole structure is compact precision

Quick Details

Condition: New

Laser Type: Fiber Laser

Applicable Material: Metal

Cutting Thickness: Depends on power source

Cutting Area: tube length 6m,8m; tube diameter 20-300mm

Cutting Speed: depending on materials and fiber power

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: Cypcut

Graphic Format Supported: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Place of Origin: Anhui, China (Mainland)

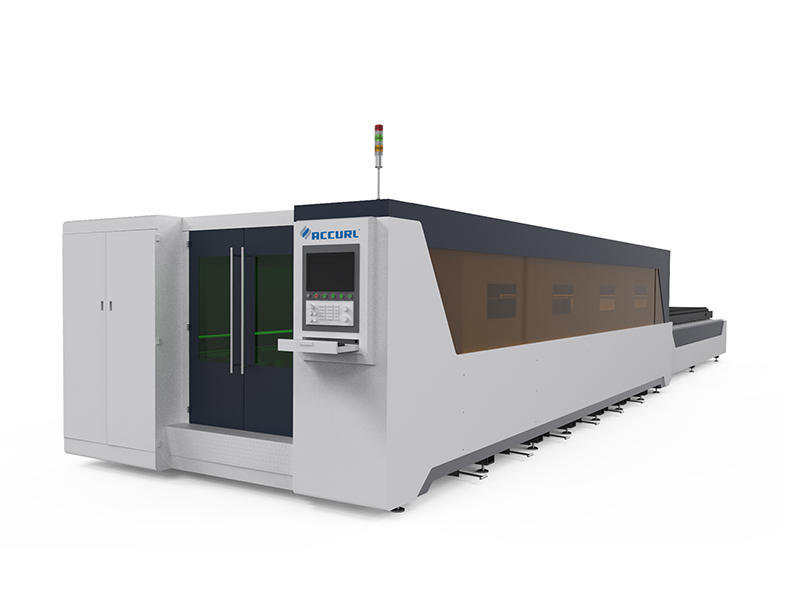

Brand Name: ACCURL

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Model: P2060A

Repeat position accuracy: ±0.03mm

Position accuracy: ±0.05mm

Fiber laser source: 1000w/1200w/2000w/2500w/3000w

Position speed: Max 90m/min

Acceleration: 1.2g

Electric power supply: AC380V 50/60Hz 3PH