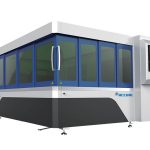

Overview

Fiber laser cutting machine has high quality beam, high reliability, good optical mode, high top power, smooth incision, good perpendicularity, it is a special cutting machine, which is suitable for stainless steel,carbon steel, Copper, Aluminum, Mo to cut and punch, the cutting speed and incision are both high level, CYPCUT program can process any graphics and text, running stably, good processing quality, high efficiency, good precision, easy operation, convenient maintenance.

Specification

500W Fiber laser source

* Auto Focusing Head from US

*Laser Power Supply

* High Precision Water cooling system

* Z- float Laser Cutting head

*High Precision Ball Screw CNC Worktable1.2*1.2M

*NcEditor Laser Cutting software and control Card

*Yaskawa driver from Japan

*Fume Extraction and Dust Collector System

*Air- dryer and Compressor (Optional)

Laser rated power: 500W

Laser wave length: 1070nm

Laser work material: fiber

Pulse frequency: 1-50Hz

Cutting format: 1200×1200mm

Z axis travel: 100mm

Top load of worktable: 200kg

Work current: 100-200A

Pulse width: 0.1-2ms

Beam divergence angle: ≤5mrad

Power instability ≤±5%

Accuracy: 0.05mm

Location speed: 18m / min

Cutting speed: 9m/ min(1mm stainless steel plate)

Top cutting speed: 8m/min(1mm carbon Steel with O2)

Repeat location precision: ±0.1mm

Cutting thickness:

stainless≤4mm

carbon steel plate≤5.0mm

copper≤2mm

aluminum≤1mm

Continuous work time: 24h

Minimum cutting width ≤0.1mm(material thickness 1mm)

Cutting worktable: Servo motor table ball screw CNC table

The whole power cost:10KW

Focusing mirror configuration: 3inch

Power supply:

3-phase

380V/50Hz/15A

Advantage

1. Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2. High cutting speed: Cutting speed is more than 12m/min

3. Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100, 000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: Fiber line transmission, no need reflect lens, save maintenance cost;

7. Easy operations: Fiber line transmission, no adjustment of optical path;

8. Super flexible optical effects: Compact design, compact and easy to flexible manufacturing requirements.

Applications

It is used widely on advertising signs production, sheet metal structures, production of high and low voltage electrical cabinet, textile machinery parts, kitchen, auto, machinery, metal technics, saw, electrical parts, glasses, spring, PCB, electrical kettle, medical microelectronics, hardware, tools, etc.

Suitable material: stainless steel, carbon steel, alloy steel, spring steel, copperplate, aluminum plate, gold, silver, titanium, etc metal plates and pipes.

Technical Support

We are pleased to offer 24hr support for all of our products. We can offer driver and software download and support, spare parts, tutorials, service, etc. We're basically here to do as much as we can to help get you up and running as quickly as possible.

Please contact us,we will try to respond to you within 24hrs.

If your enquiry is of a more urgent nature, we invite you to contact us by telephone: (+86)-27-87611146. Technical Support is available in Chinese (Mandarin) or English.

FAQ

1.Q:What is the warranty of the machine?

A:Questt Lasers have a warranty for 1-2 years.

2.Q:Are you a factory or trading company?

A:ACCUR is a factory for 22 years.Got import and export License.

3.Q:How about the quality?

A:ACCURL Lasers Technology is from Germany.High quality best price.

4.Q:What is your after-sale service?

A:If needed,ACCURL offer door to door service !we can send engineers to your factory for assembling ,adjusting and training!

5.Q:How do i get technical support after purchasing?

A:Questt Lasers offer online service in English through Skype,WhatsAPP,Wechat or Email etc .If need remote operation,we can use TeamViewer software.