Detailed Product Description

| Model Number: | KJG-1530DT-700W ACCURL | Working Range: | 1500x3000mm |

|---|---|---|---|

| Laser Type: | USA NLIGHT Fiber YLS-700w | Linear Guide: | Taiwan HIWIN |

| Reduction Gears: | French MOTOREDUCER | Keywords: | 700w Fiber Laser Tube Cutting Machine |

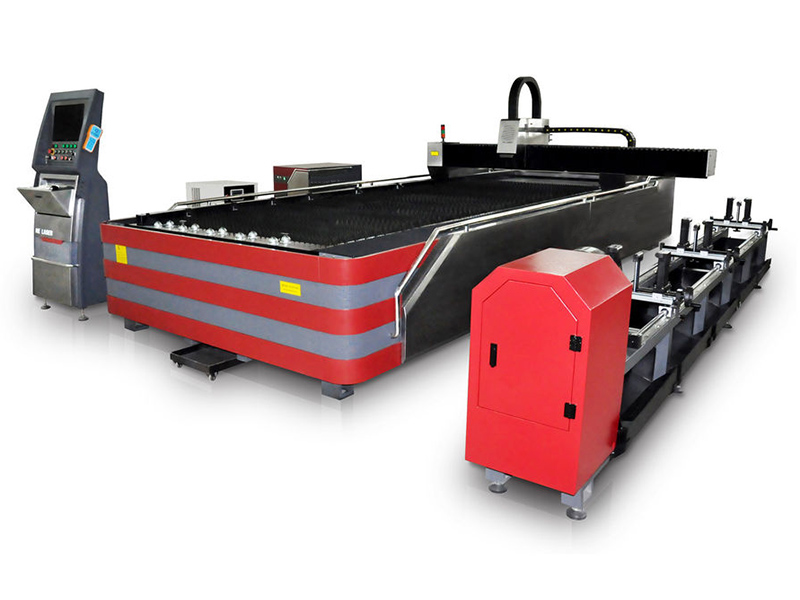

700w Fiber Laser Tube Cutting Machine for 3mm Stainless steel

LASER TUBE CUTTING

Accurl’s introduces its newest generation in tubes and profiles processing technology – the Fiber Laser Tube Cutting System. With over 30 years of experience in design and manufacturing experience in tube cutting technology, Accurl is specialized in solutions for the Tube and Pipe industries, and the new Laser Tube Cutting Line is the ultimate solution for joining multiple machining processes in one system for maximum flexibility, automation and performance.

Main Features

The ACCURL@ Fiber Lasers bring a cost eᴀective, low-maintenance, low operating cost and environ-mentally friendly solution to your organization. Our ἀber laser machines provide quality cutting and tolerances with minimal productivity loss between jobs, equating to a higher re turn on investment.

1. Acceleration speed: 19,6 m/s2 (2G).

2. Maximum simultaneous positioning speed: 160m/min.

3. Precision: + - 0.05 mm.

4. Energy efficiency: greatly reduced power consumption.

5. Excellent cutting quality for fine thic kness and medium thickness sheet metals.

6. IPG Resonator. Power output from 1 kw to 6 kw .

7. Precitec light cutter cutting head with po wer output up to 2kw.

8. Precitec HP cutting head for po wer output of more than 2kw.

9. Fully enclosed and cabinned to ensur e máximum operator protection.

10. Effective high to low pressure gas exchange system.

11. Capacitative Sensor, high pressure cutting head.

12. TCI Cutting parameter tables.

13. Pre-cut film protector.

14. Automatic mechanized Nesting power output control function (edges, start-ups).

15. Automatic time and unit cost calculation function.

16. Network connection from external.

17. Automatic table exchanger (included in series models).

18. Smoke extraction (included in series models).

19. 3 point reference sensor (sheet metal rotation detector).

20. Piercing Sensor.

21. Collection of work pieces and trimmings.

22. Dual proportional valve control system for different gas pressures and special system for high pressure cutting.

STANDARD EQUIPMENT

1. 3 Axis (X, Y, Z)

2. FAGOR 8055 CNC control unit

3. Servo Motor

4. Auto - focus cutting head

5. Laser Source

6. Chiller Unit

7. Clean-dry air system

8. Safety Cabinet

OPTIONAL EQUIPMENT

1. Linear motor technology

2. IPG 0.5 kW, 1 kW, 2 kW, 3 kW, 4 kW and 6 kW laser source options

3. Extraction unit.

4. Light protection barrier

5. Pneumatic sheet support system for easy sliding

6. Air conditioner for automation panel

7. Metalix, Almacam etc. CAD/CAM software

8. Nozzle changer

Standard Euipment

1. CUTTING TABLE

The dual cutting table system is designed for in-creasing your workflow and reducing time spent on placing and removing materials. Cutting table exchange speed can be adjusted according to thickness of materials.

2. NOZZLE CLEANER

Keeping your machine cutting quickly and cleanly is important. Our nozzle cleaner helps improve the life of your nozzles so your cuts stay consistent, longer.

Product Application

1. Applicable Fields

Applicable for high-speed cutting on various metal plates or tubes such as S/S, carbon steel, galvanized sheet,electrolytic plate, aluminum plate, steel, brass, alloy plate, rare metals and other materials;

2. Widely used

Widely used in kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and metal processing.

SPECIFICATIONS

| Model | KJG-1530 / IPG 700w | |

| Maximum cutting capacity | Mild steel | 8mm |

| Stainless steel | 3mm | |

| Aluminyum | 2.5mm | |

| Copper | 1.5mm | |

| Laser Power | YLR-700Watt | |

| Max running speed | 40/min | |

| Work piece dimensions | 1500 x 3000mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 1.2G (12m/s2) | |

| Absolute positioning accuracy | ± 0.03 mm | |

| Max. load capacity | 1550 kg | |

| Fume extractor | 1000 m3/hour | |

| Laser Cutting Head | RayTools BM110 from Switzerland | |

| Feed rate | Programmable up to 30 m/min. | |

| Applied Materials | Thin mild steel, Stainless steel, Aluminum, Copper plate | |